AUTO BEAM SAW

Automatic Beam Saw UBS 3200 Auto +

The Automatic Beam Saw UBS 3200 Auto + from Umaboy is the ultimate solution for manufacturers seeking high-speed, high-precision, and automated panel cutting. Designed for both modular woodworking and solid wood panel processing, this CNC-controlled beam saw ensures seamless productivity, minimal waste, and maximum efficiency in every cut.

Perfect for cutting MDF, plywood, HDF, particle boards, and laminated sheets, this machine meets the demands of large-scale manufacturers across India and abroad.

- SPECIFICATION

Key Features of Automatic Beam Saw UBS 3200 Auto + Beam Saw

High-Precision CNC Cutting

The Automatic Beam Saw UBS 3200 Auto + is equipped with CNC technology that ensures precise, chip-free, and smooth cuts every time. The computerized control system eliminates human errors, providing accuracy in cutting dimensions, making it perfect for modular furniture, cabinetry, and interior woodwork.

Heavy-Duty Main Saw Motor (15kW, 18.5kW Optional)

The high-powered main saw motor drives the 400mm diameter blade with optimal cutting speed and efficiency. For operations requiring higher power output, an 18.5kW motor upgrade is available, ensuring smooth cutting for thicker and denser wooden panels.

Automatic Material Handling with Pneumatic Side Aligner

The pneumatic side aligner ensures the precise positioning of workpieces before cutting. This automated alignment system minimizes errors, optimizes panel positioning, and improves operational efficiency, making it ideal for bulk production environments.

Efficient Cutting Capacity (3200mm Cutting Length)

With a cutting length of 3200mm, the Automatic Beam Saw UBS 3200 Auto + can handle large-sized wood panels with ease. Whether you’re cutting MDF, HDF, plywood, particle board, or laminated sheets, this machine ensures accurate cutting with minimal material wastage.

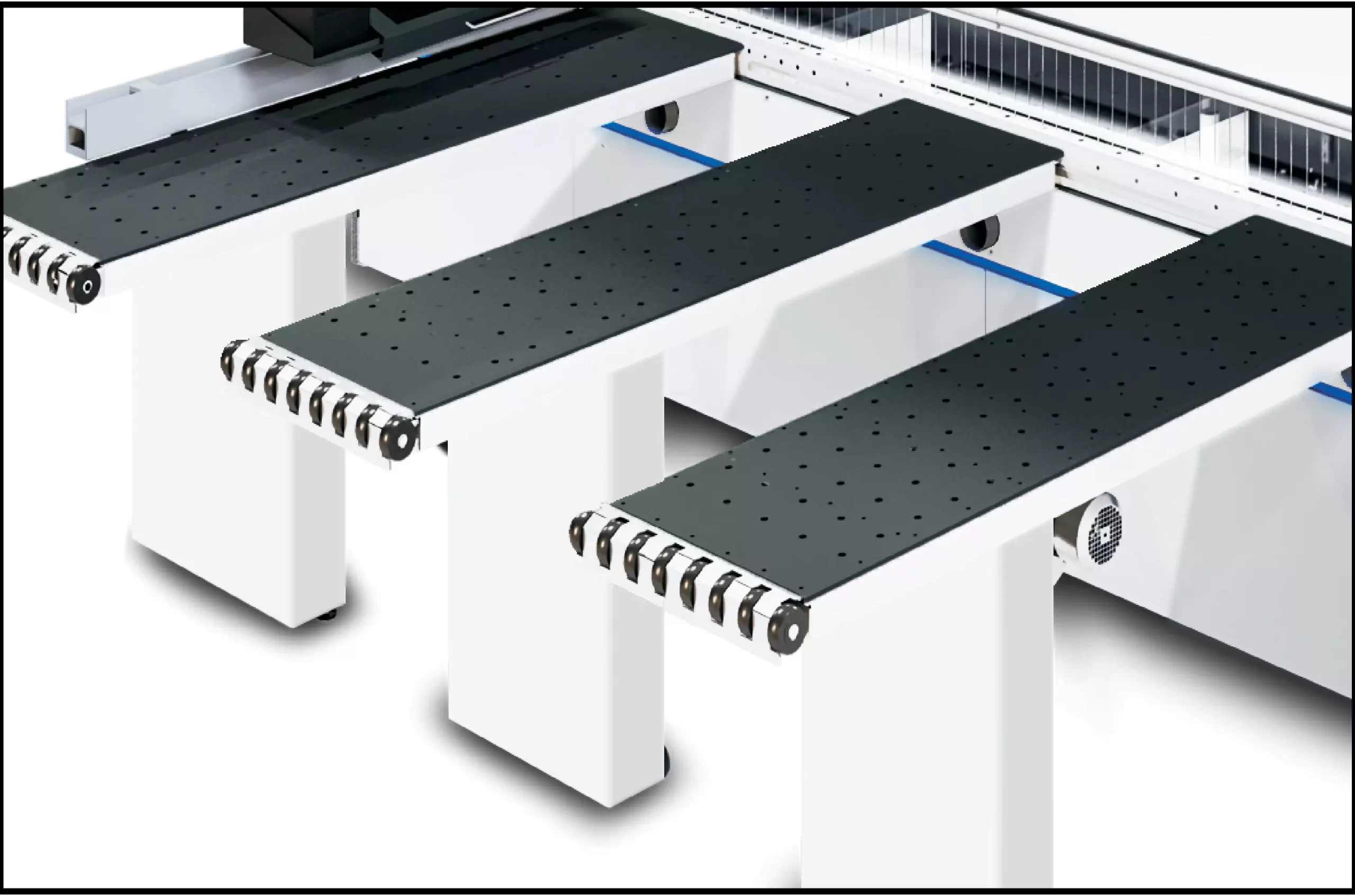

Advanced Air Floating Platform with 2.2kW High-Pressure Blower

This air cushion table system reduces panel friction, making it effortless to move heavy and delicate wooden sheets across the cutting table. The 2.2kW high-pressure blower enhances ease of operation, prevents surface damage, and ensures a smooth material flow.

Dual Blade System for Maximum Efficiency

The UBS 3200 AUTO+ comes with a two-blade system, enhancing cutting accuracy and efficiency:

1. Main Saw Blade (400mm) – Handles the primary cutting process with maximum precision.

2. Groove Saw Blade (160mm) – Pre-cuts the panel before the main blade, reducing splinters and ensuring a cleaner cut finish.

Blade Carriage with High-Speed Forward Motion

The high-speed blade carriage movement ensures rapid and efficient cutting cycles, allowing manufacturers to process higher volumes of wood panels in less time. This feature is critical for industrial woodworking units looking to enhance productivity.

Smart Gripper System with 13 Grippers

The 13 -piece gripper system securely holds the wood panels in place during the cutting process. This minimizes vibrations and prevents material shifting, ensuring highly accurate cutting and reducing material waste.

Energy-Efficient Operation (Total Power Consumption – 23kW)

Despite its high performance and automation, the UBS 3200 AUTO + is engineered for energy efficiency. The optimized power management system ensures lower operational costs while delivering maximum output and productivity.

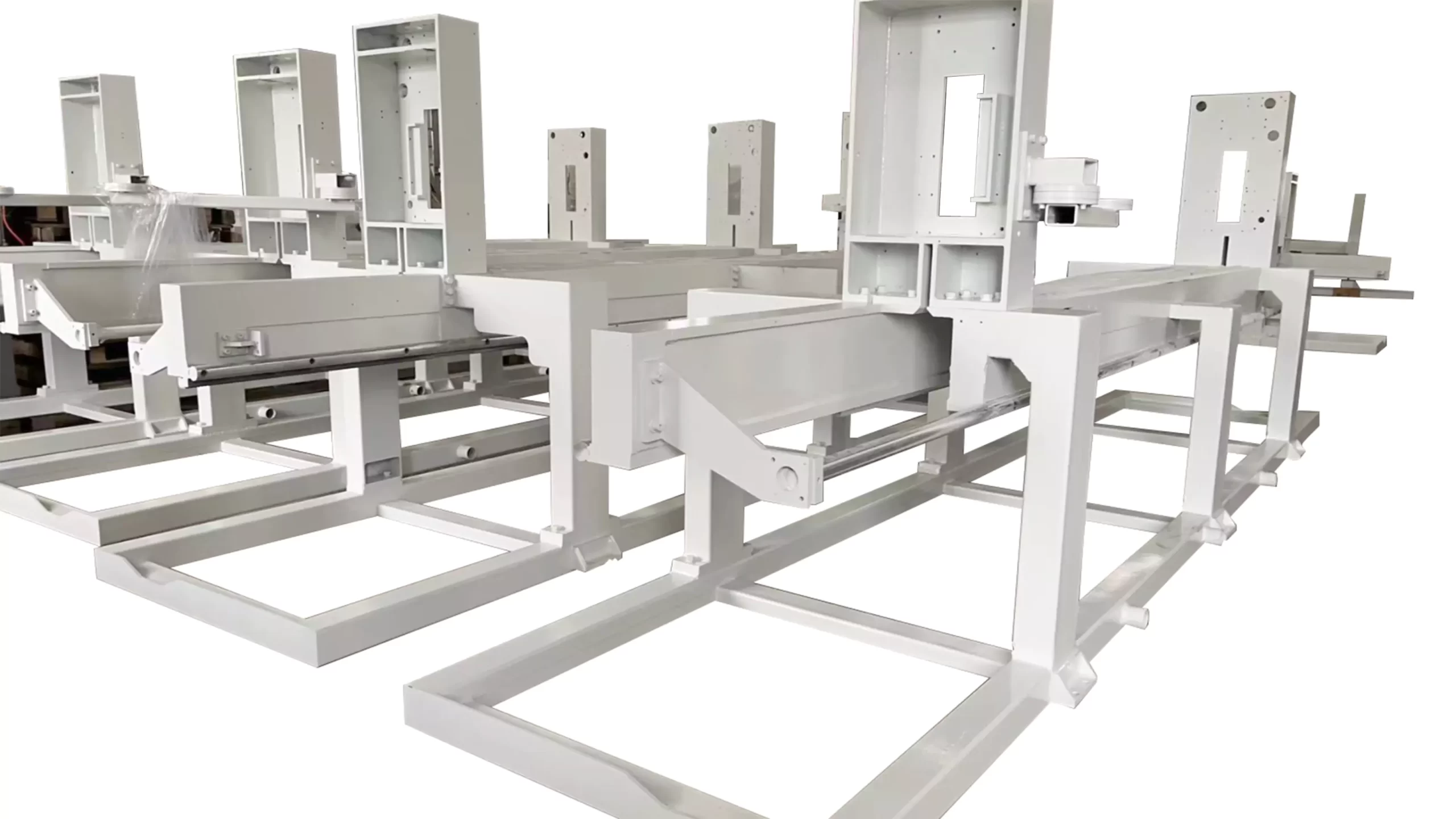

Heavy-Duty Structure & Robust Durability

Built with high-quality materials, the Automatic Beam Saw UBS 3200 Auto + is designed for continuous industrial operation. Its strong frame structure ensures stability, vibration-free performance, and long-lasting reliability even under high production demands.

HIGHLIGHTS

Optimizing software

- The machine is equipped with professional optimization software

to ensure efficient handling and convenient operation. Additionally,

it is compatible with other globally recognized software for further

application.

- The software is incredibly powerful and user-friendly, offering a

range of features such as comprehensive work process management

with detailed reports, simulation of cutting patterns, display of error

messages, printing of barcodes, and numerous other advantages.

Pressure roller group

- The presence of steel balls on the table surface, along with a fan, guarantees smooth movement of panel stacks by providing constant air circulation.

- Three pipes are linked to three float tables, and a air blower positioned beneath the table provides an ample supply of air.

Machine body

- Adequate metal fabrication process is essential to ensure the precision and longevity of a specially designed machine body, which is constructed using high tensile strength steel.