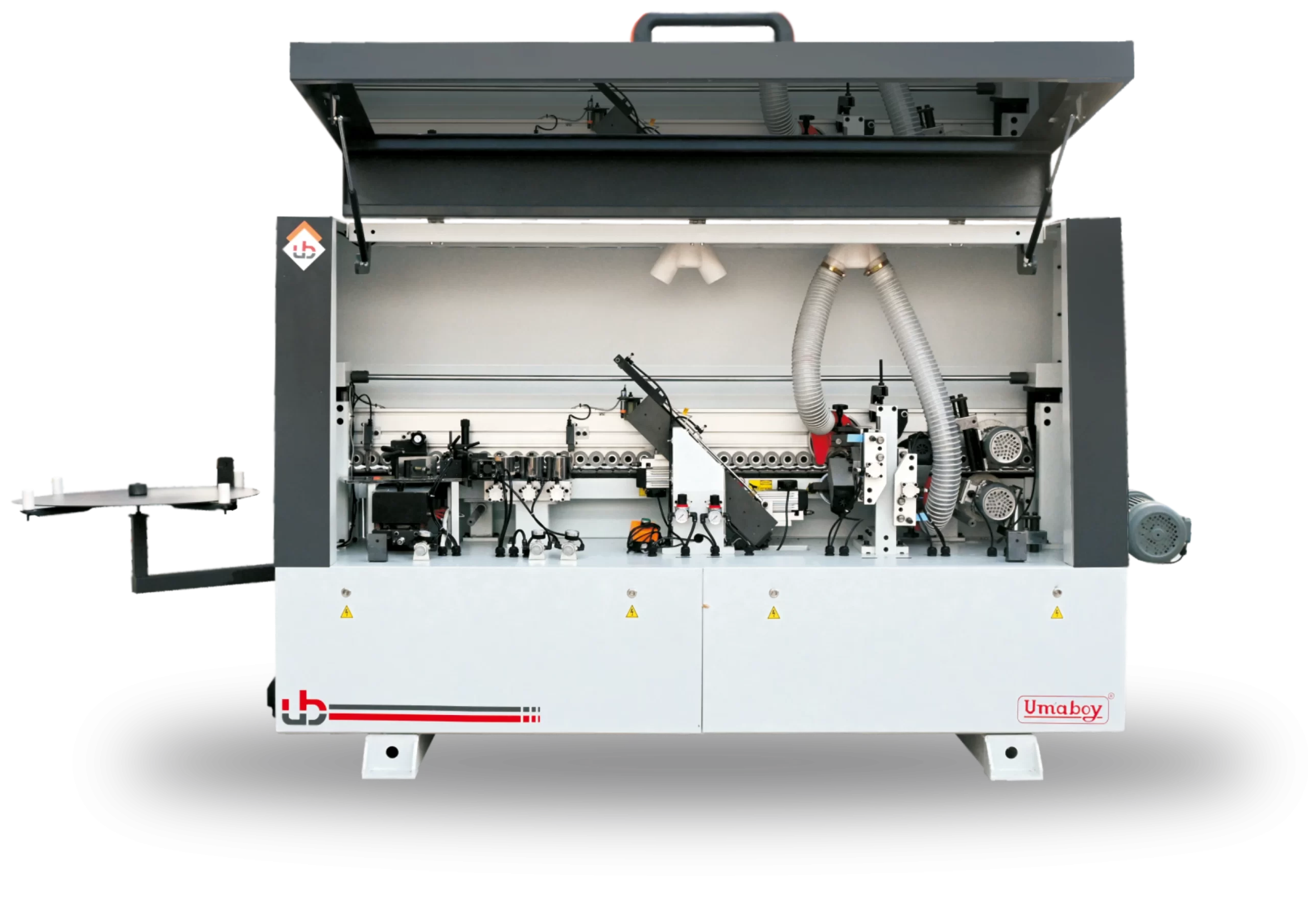

AUTOMATIC EDGEBANDER

Best Edge Banding Machine Umaboy UEB 240-S Automatic Edge Bander - Reliable Edge Finishing for Your Workshop

- SPECIFICATION

Basic Function of a Machine

The UEB 240 S Edge Bander Best Edge Banding Machine is a high-speed, heavy-duty edge banding machine designed for modular furniture manufacturers and woodworking professionals. Engineered for precise finishing and long-lasting performance, this model is ideal for applying PVC, ABS, veneer, and melamine edge bands with absolute consistency. It’s built for factories that demand speed, safety, and superior quality in panel finishing.

PRODUCT IMAGES

Key Specifications of the Best Edge Banding Machine from Umaboy UEB 240-S

| Specification | Value |

| Electric Level | 415-220/50 Hz |

| Edge Material Thickness | 0.4-3 mm |

| Panel Thickness | 10-50 mm |

| Minimum Width of the Panel | 75 mm |

| Minimum Length of the Panel | 130 mm |

| Conveyer Speed | 18 m/min |

| Conveyer Thickness Adjustment | Electric |

| Conveyer Up / Down Power | 0.37 kw |

| Total Electric Power | 6.5 kw |

| Total Air Pressure | 6-8 bars |

| End Cutting Unit Power | 2 x 0.55 kw |

| Top/Bottom Fine-Trimming Power | 2 x 0.55 kw |

| Buffing Unit Power | 2 x 0.37 kw |

| Overall Size (L x H x W) | 3400 x 1600 x 1000 mm |

HIGHLIGHTS

Glue Unit

This unit ensures a uniform and controlled application of glue across the edge. The UEB 240 S uses a precision glue pot system that melts and applies adhesive with accurate temperature regulation, reducing glue wastage and ensuring strong bonding. The closed glue pot mechanism prevents glue carbonization and enhances finish quality.

- The Teflon-coated gluepot effectively prevents glue wastage and simplifies the removal of burnt glue, ensuring smooth operation. With a 2 kg capacity and a 1.5 kW plate heater, it provides efficient and reliable performance for high-quality adhesion.

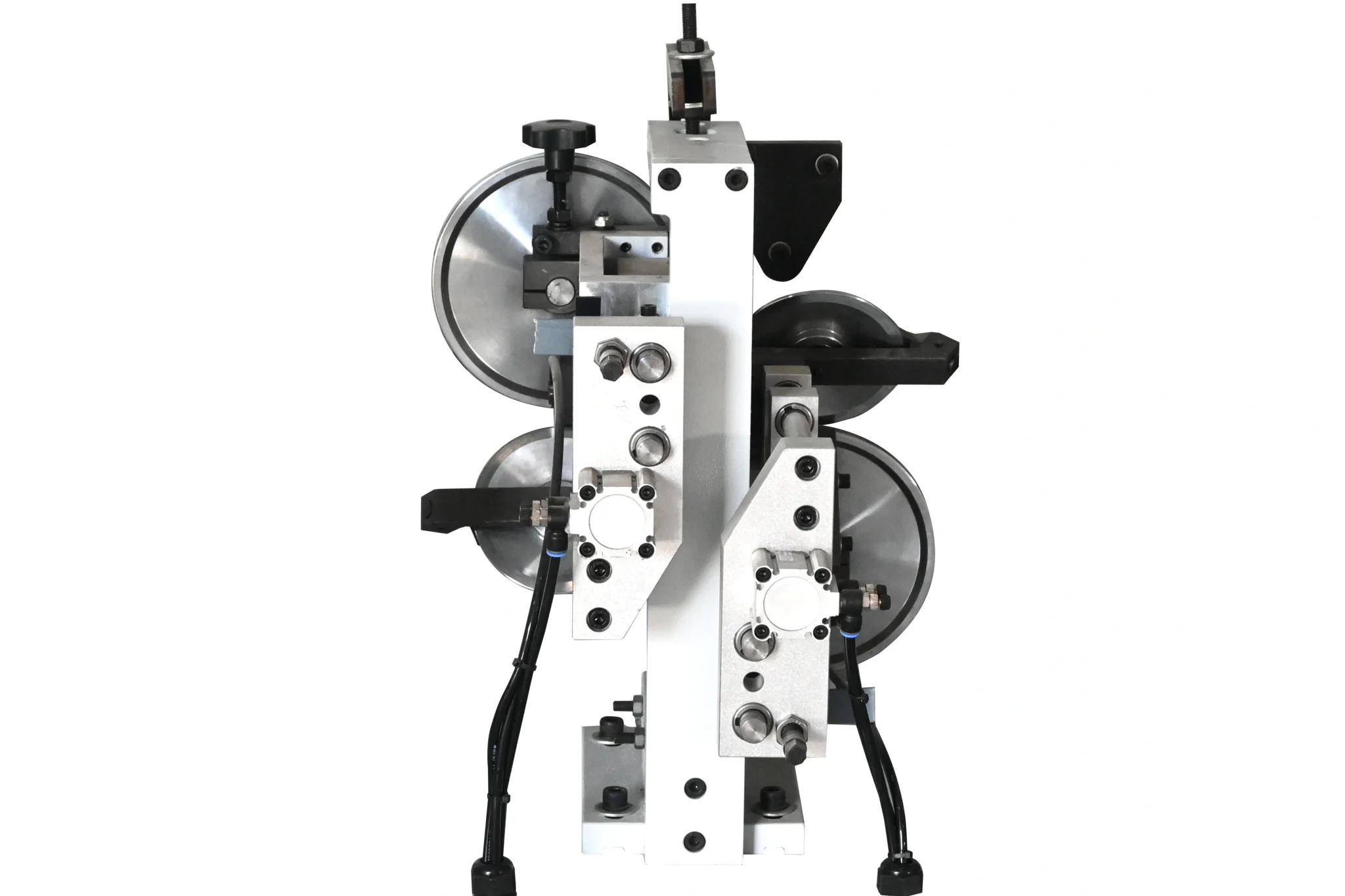

Pressure roller group

Once the glue is applied, the pressure rollers press the edge band firmly onto the panel. This system uses multiple rubberized rollers to ensure bubble-free, wrinkle-free, and distortion-free application. These rollers work together to deliver perfect adhesion, even on curved or laminated panels.

- The pressure roller group comprises three rollers, with the first having a diameter of 150 mm and the remaining two featuring diameters of 100 mm. This configuration ensures optimal pressure distribution for consistent edge bonding.

End cutting

- The unit is designed to trim excess PVC from both ends of the panel, featuring high-frequency motors with 0.55 kW power and 12,000 rpm. It is equipped with 150 mm diameter saw blades for precise and efficient cutting.

The dual-blade end cutting system trims the front and rear edge banding precisely at 90°, delivering a clean and professional finish without chipping. Operated by two independent high-speed motors, this unit guarantees accurate cuts even at high conveyor speeds, making it ideal for bulk production.

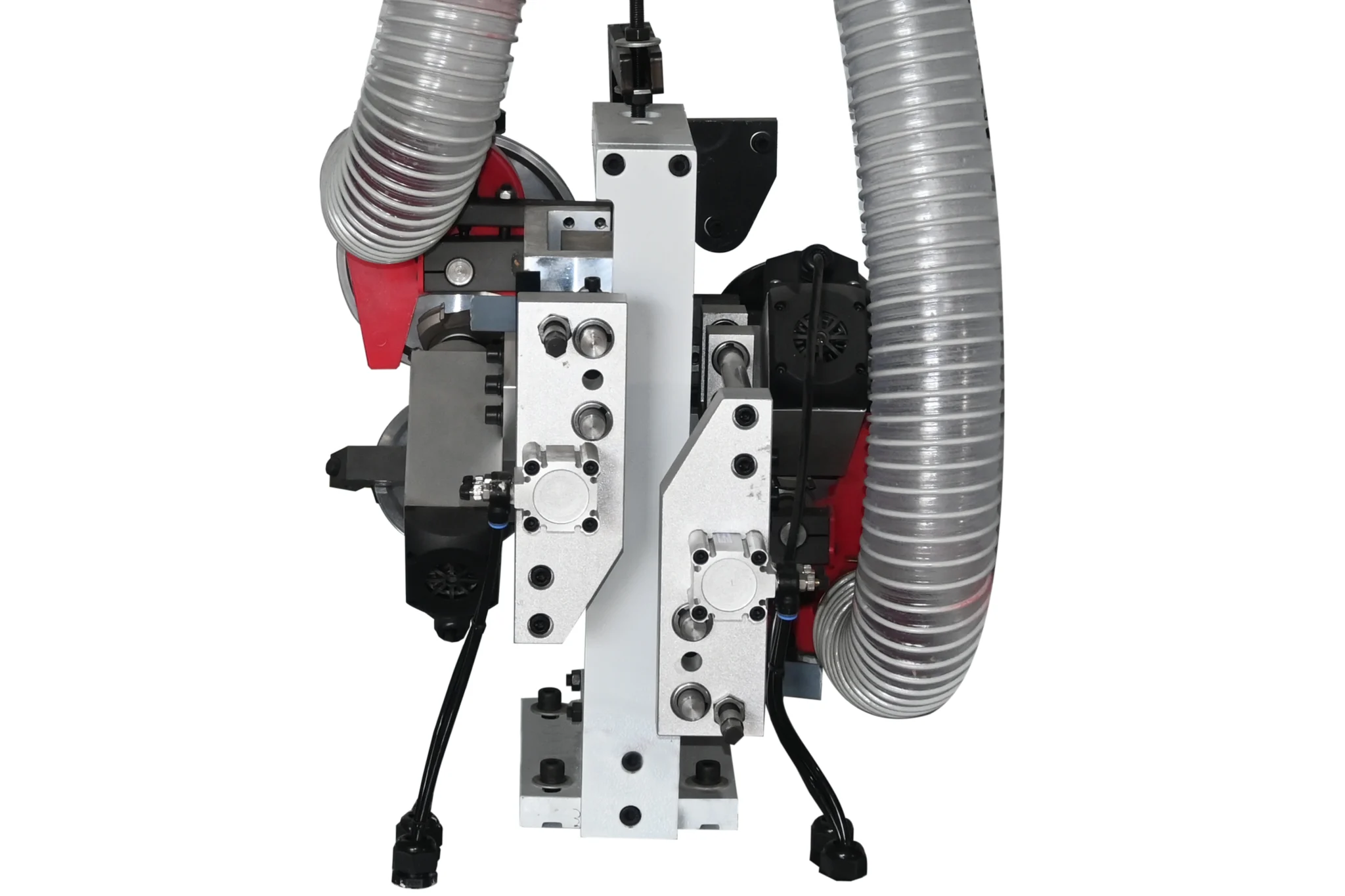

Fine Top/Bottom Trimming

This unit removes excess edge banding from the top and bottom edges of the panel. Using ultra-sharp carbide cutters, it trims without damaging the panel surface. Adjustable settings make it compatible with edge thicknesses from 0.4mm to 3mm, ideal for varying project needs.

- Equipped with two high-performance frequency motors, a suction hood, and a vertical guide plate for enhanced precision and efficiency.

PVC Scraping unit

PVC scrapping efficiently removes excess material from the top and bottom edges for a clean, smooth finish.

For PVC and ABS banding, the scraper system smooths out the trimmed edge to remove cutting marks. It enhances the surface finish and ensures the edges feel flush and smooth to the touch, matching the panel surface seamlessly. A must-have for high-end modular furniture work.

Buffing unit

The twin buffing wheels give the final polish to the edge. They remove any remaining glue marks and deliver a high-gloss, showroom-quality finish. Buffing also enhances durability and protects the panel edges from daily wear and tear.

- Finishing the edge looks dimensional and attractive with this process.

Who Should Use UEB 240 S?

This model is ideal for:

Modular furniture factories

Office furniture production lines

MDF and laminated board manufacturers

High-volume cabinetry workshops

Have Any Question ?

WE ARE HAPPY TO HELP !

Explore More Machines from Umaboy

Looking for more woodworking machinery? Check out these top models:

- Automatic Edge Bander UEB 310 C – For faster operations and higher edge thickness handling.

- Manual Edge Bander Machine – Budget-friendly option for small workshops.

- Sliding Panel Saw 3200 A++ – High-precision panel cutting solution.

- Beam Saw UBS 2800 Auto – Ideal for bulk cutting of large panels.

Visit our Modular Machinery page to explore the complete product range.