YOUR DESIRED MACHINES

Nesting CNC Router Machine – Precision, Speed & Profitability in One Powerful Solution

Upgrade your production line with our Nesting CNC Router Machine, engineered to automate furniture panel cutting with unmatched accuracy and speed. Ideal for modular furniture manufacturers, plywood processing units, and large-scale carpentry workshops, this machine is built for high-volume, precise nesting operations.

CATEGORY

MODULAR FURNITURE MACHINERY

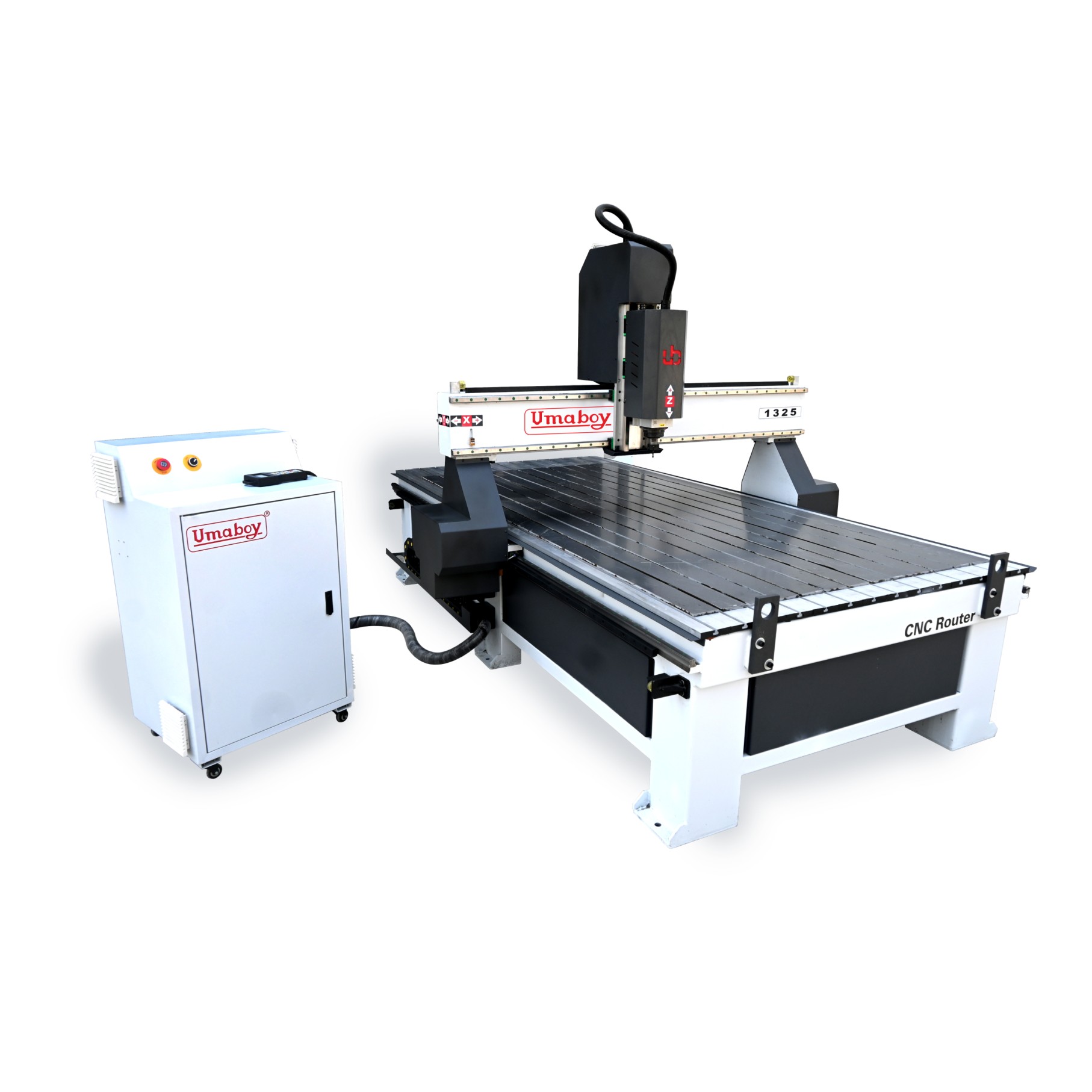

CNC Router 1325-A

Designed for standard precision routing, cutting, and engraving.

CNC Router 1325- SS

Enhanced with higher spindle power and speed for heavy-duty processing.

Built at India’s Leading Woodworking Machine Manufacturing Facility

Every CNC Nesting Router machine is manufactured at Umaboy’s state-of-the-art facility in Ahmedabad, Gujarat, equipped with CNC machining centers and stringent QC protocols. Our machines are trusted across India and exported globally.

Have Any Question ?

WE ARE HAPPY TO HELP !

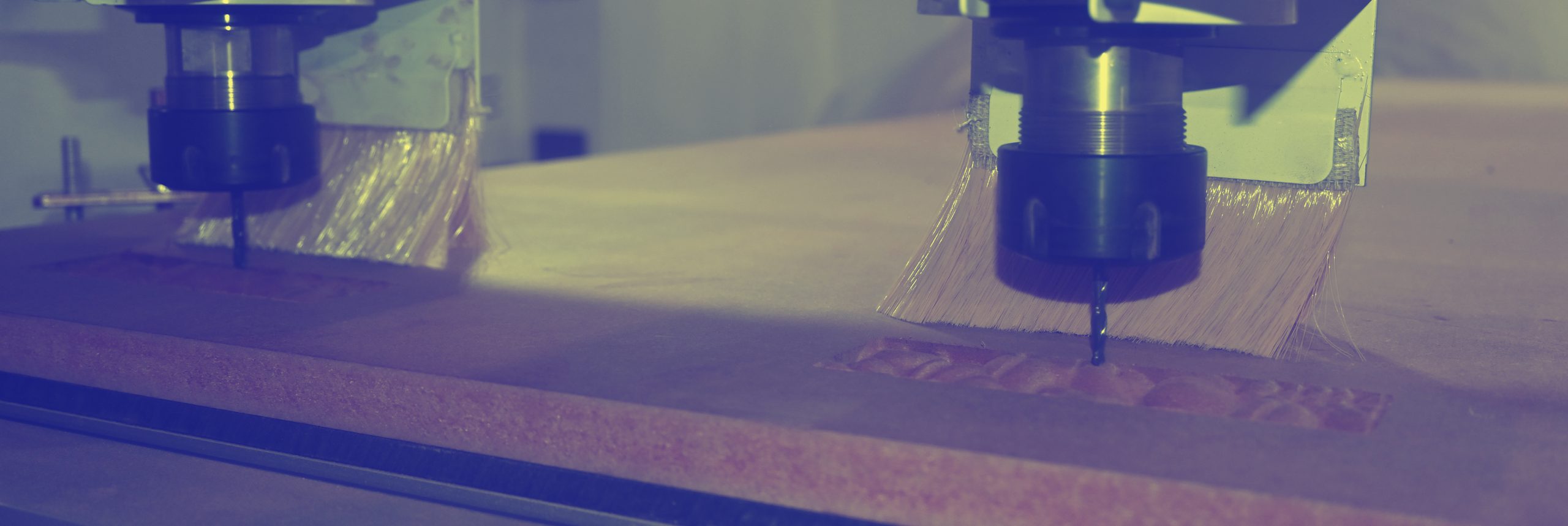

About CNC Router Machine

The CNC Router Machine, manufactured with precision, features a robust, sturdy, and dependable body. As a leading manufacturer of CNC Router Machine, we ensure the imported high-precision ball screw gap guarantees smooth movement, ensuring the high precision of the machine tools. The Automatic CNC Router is equipped with a powerful cutting capability, low noise, and renowned domestic water-cooled brushless spindles, guaranteeing long-lasting operation. The high-performance motor is designed to ensure the machine’s high speed and precision. Every accessory is meticulously chosen to reduce the preferred failure rate, making this machine a top choice for precision tasks. Enhance your production capabilities—buy CNC Router Machine today for unmatched precision and efficiency.

Application of CNC Router Machine

-

Features

- Computer Control: Operates via computer software, allowing for precise and repeatable cuts based on digital designs.

- Variable Speed Spindle: Adjusts cutting speeds for different materials and applications.

- Multi-Axis Capability: Typically 3, 4, or 5 axes for complex and detailed cuts and engravings.

- Automatic Tool Change: Swaps tools automatically for different tasks, enhancing efficiency.

- Large Worktable: Provides ample space for working on various sizes of materials.

Advancements:

- Enhanced Software: Advanced CAD/CAM software for more intuitive design and control.

- High-Speed Motors: Improved cutting speeds and efficiency.

- Precision Sensors: For real-time monitoring and adjustment of cutting parameters.

- Better Materials: Use of robust materials and components for greater machine durability and accuracy.

- Integration with IoT: Enables remote monitoring and control, improving connectivity and ease of use