CNC ROUTER

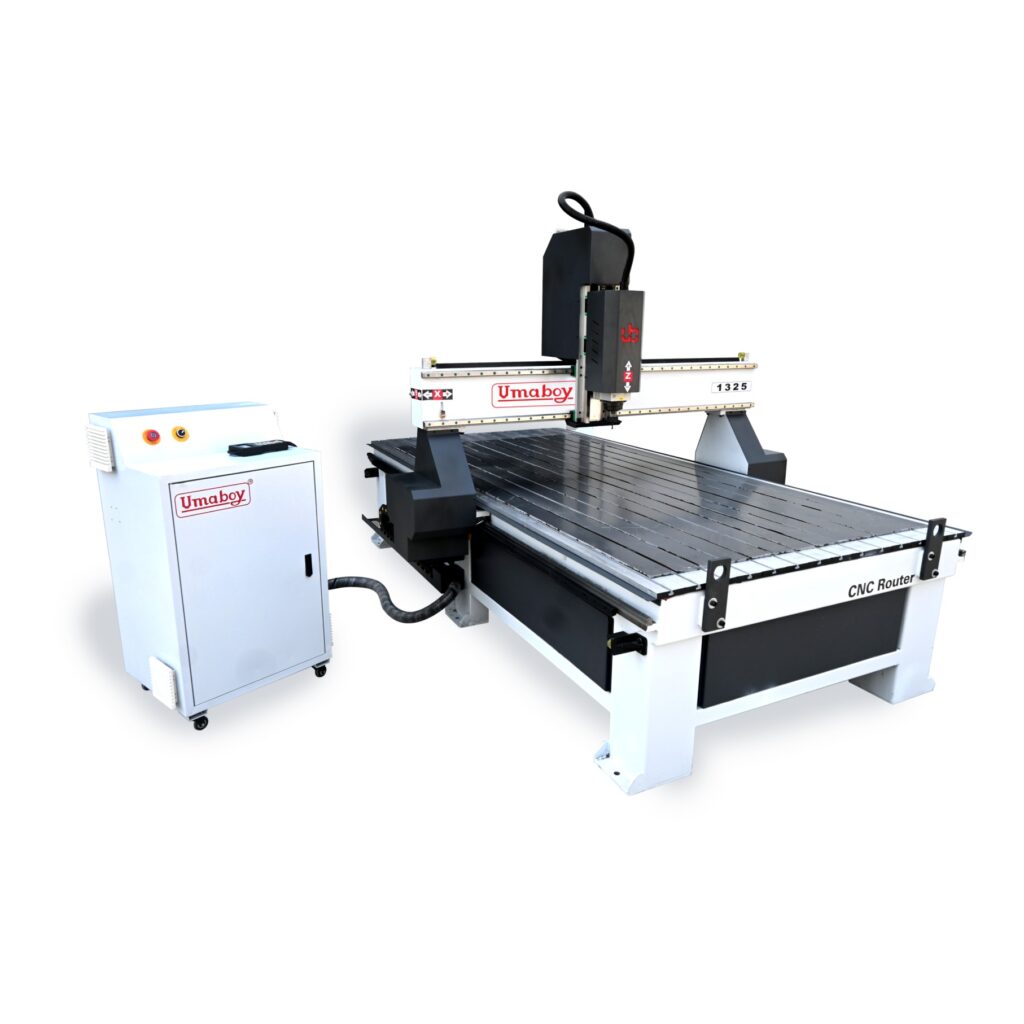

Nesting CNC Router Machine UCR 1325 A

- SPECIFICATION

CNC Router Machine1325 A

The CNC Router Machine UCR 1325A, built with premium-quality components, is a highly versatile solution for cutting and engraving a wide range of materials, including plastic, acrylic, composite panels, wood, copper, and more. As a leading manufacturer of the CNC Router Machine UCR 1325A, we ensure that it meets the specific demands of both the advertising and woodworking industries. Featuring a robust steel structure, this CNC router is particularly well-suited for working with hardwoods, such as rosewood, making it ideal for furniture manufacturing and interior decoration. Additionally, its advanced vacuum holding system and efficient dust collector enhance productivity, making it an excellent choice for large-scale furniture production.

The Auto Edge Banding Machine UEB 990 PUR is the ultimate solution for manufacturers seeking flawless edge finishes with the power of PUR (Polyurethane Reactive) glue technology. This high-performance machine combines speed, accuracy, and durability—making it ideal for modular furniture, kitchen cabinets, wardrobes, and more.

With a maximum conveyor speed of 23 m/min and an intelligent configuration of trimming and corner rounding units, this machine is built to handle continuous production cycles while maintaining top-tier finishing quality on every panel edge.

Nesting CNC Router Machine UCR 1325 A Highlights

PUR Glue Unit

Ensures a durable, water-resistant, and heat-resistant bond, ideal for premium edge finishing on modern furniture panels.Pre-Milling Unit (2×2.2 kW)

Guarantees smooth and clean panel edges by removing imperfections before edge banding.End Cutting Unit (2×0.55 kW)

Precisely trims the leading and trailing edges for a perfect alignment of the edge tape.Top & Bottom Fine Trimming Units (2×0.55 kW)

Deliver precise trimming of top and bottom edges, ensuring a flush finish on all sides.Top & Bottom Rough Trimming Units (2×0.55 kW)

Remove excess banding material for accurate profiling before fine trimming.Corner Rounding Unit (2×0.3 kW)

Achieves smooth corner edges, eliminating sharpness and enhancing safety and aesthetics.Grooving Unit (4 kW)

Cuts a groove for panel back or sliding door applications with high precision using a 17 + 9 mm blade.Buffing Units (2×0.37 kW)

Final buffing ensures a clean, polished look free of glue residue or edge marks.Liquid Spraying System

Anti-adhesive liquid spray before buffing ensures a spotless surface, enhancing the final finish.Conveyor with 3-Speed Control (14/18/23 m/min)

Adjustable speed settings for flexible production requirements and optimal output.

CNC Router Machine UCR 1325 A Specifications

| Specification | Details |

| Model | UEB 990 PUR |

| Electric Level | 415-220V / 50 Hz |

| Edge Material Thickness | 0.4 – 3 mm |

| Panel Thickness | 10 – 60 mm |

| Min. Width of Panel | 50 mm |

| Min. Length of Panel | 120 mm |

| Conveyor Speed | 14 / 18 / 23 m/min |

| Conveyor Thickness Adjustment | Electric |

| Conveyor Up/Down | 0.37 kW |

| Total Electric Power | 30 kW |

| Total Air Pressure | 6 – 8 bars |

| Pre-Milling Motor Power | 2 × 2.2 kW |

| End Cutting Unit Power | 2 × 0.55 kW |

| Top/Bottom Fine-Trimming Power | 2 × 0.55 kW |

| Top/Bottom Rough-Trimming Power | 2 × 0.55 kW |

| Corner Rounding Unit Power | 2 × 0.3 kW |

| Grooving Unit Motor Power | 4 kW |

| Max Depth of Grooving | 17 mm + 9 mm blade |

| 1st Buffing Unit Power | 2 × 0.37 kW |