Looking to speed up your modular panel processing with flawless precision? The U-612KS CNC Six Sided Drilling Machine with ATC (Automatic Tool Changer) is engineered for high-throughput, multi-face drilling, grooving, and routing operations—all in one cycle.

Designed for furniture manufacturers, modular kitchen makers, and wardrobe producers, this automatic six-sided drilling machine with ATC boosts efficiency by eliminating manual tool changes. It’s ideal for processing ready-to-assemble furniture components with zero alignment errors.

| Feature | Details |

| Drilling Sides | Top, Bottom, Left, Right |

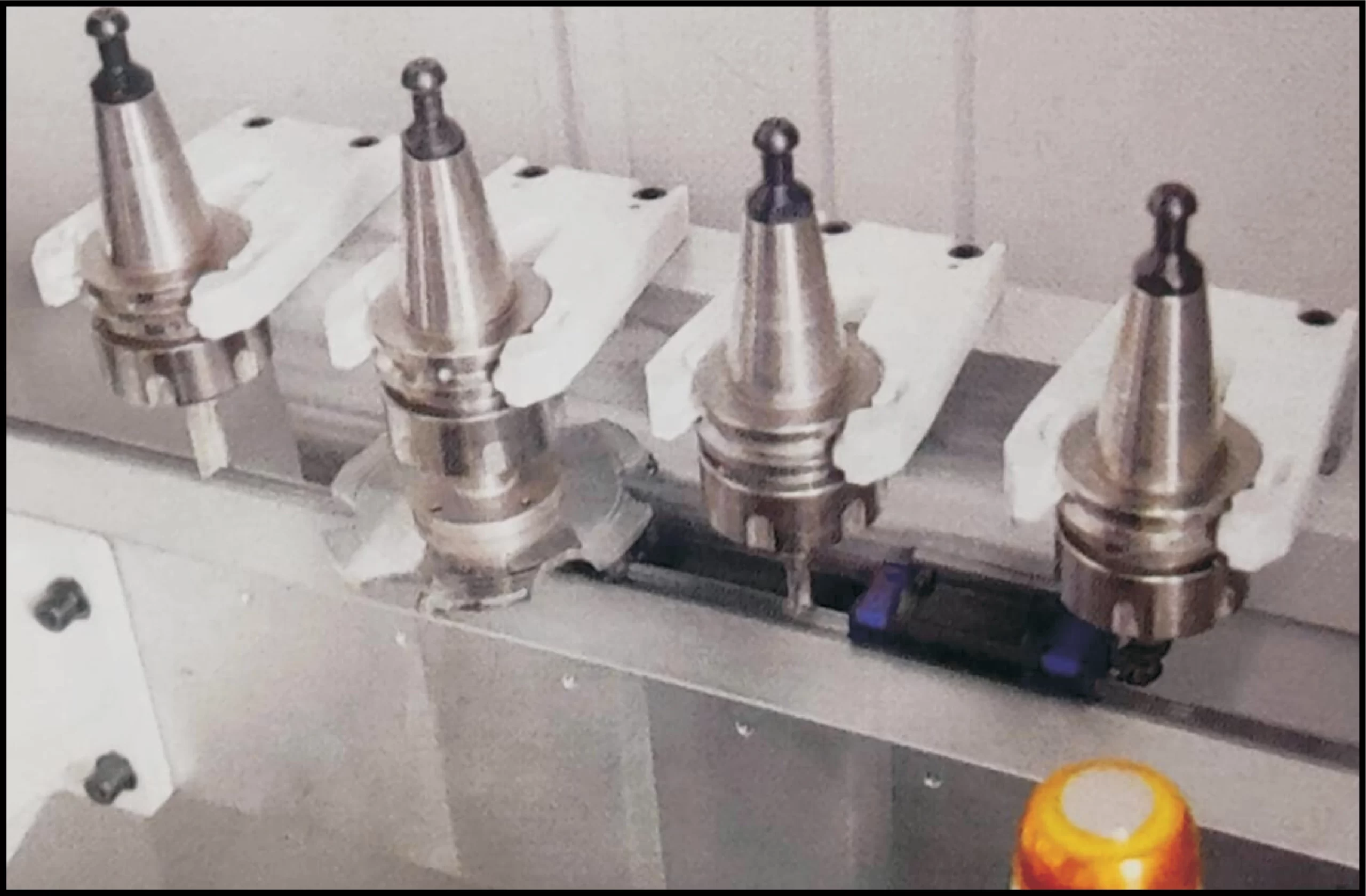

| Tool Changer | Automatic (ATC) |

| Max Panel Size | 2500 x 1200 mm |

| Min Panel Size | 300 x 60 mm |

| Max Panel Thickness | 50 mm |

| Spindles | High-speed Italian spindle motors |

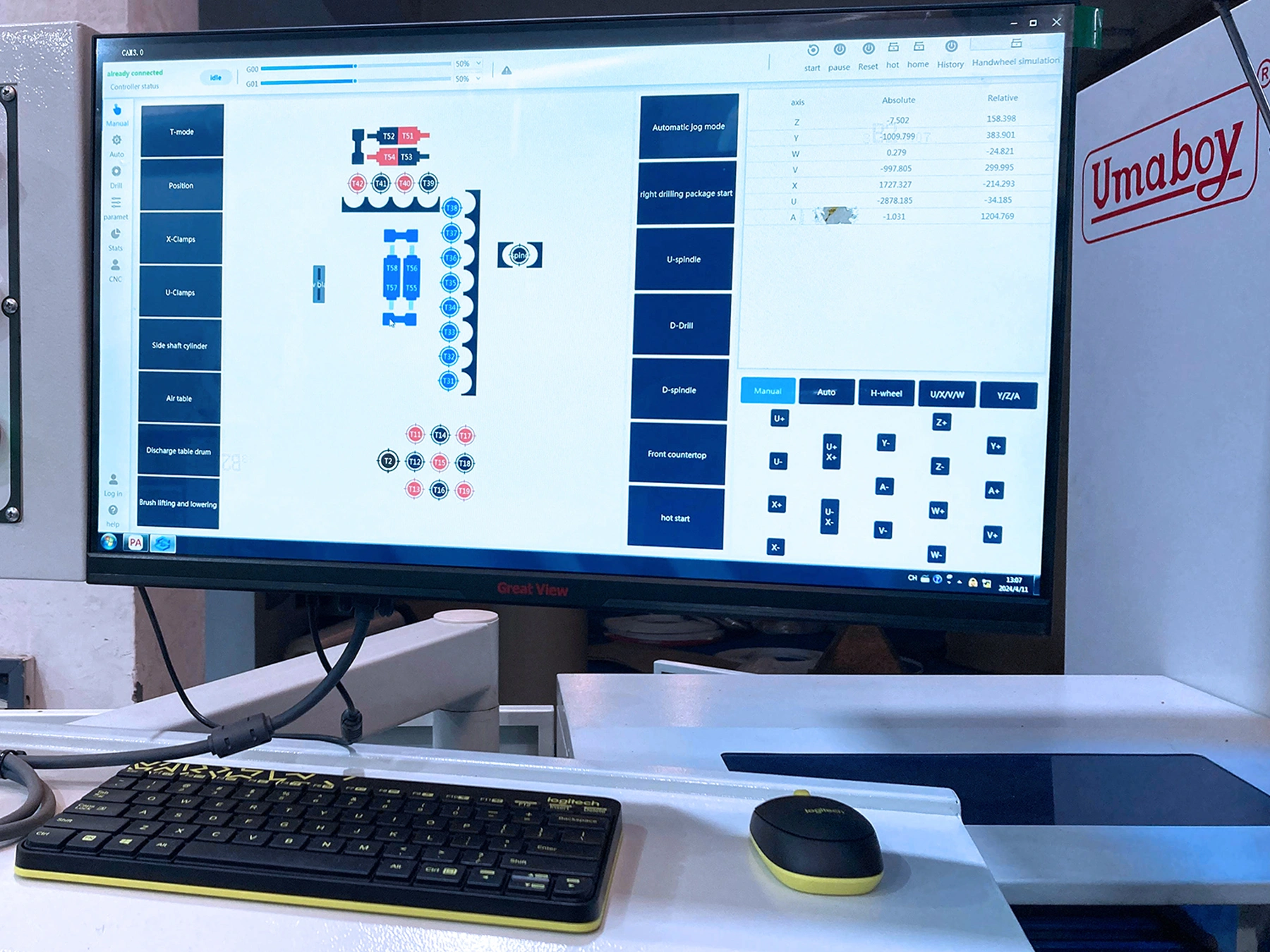

| Control System | Industrial PC with Umaboy CNC UI |

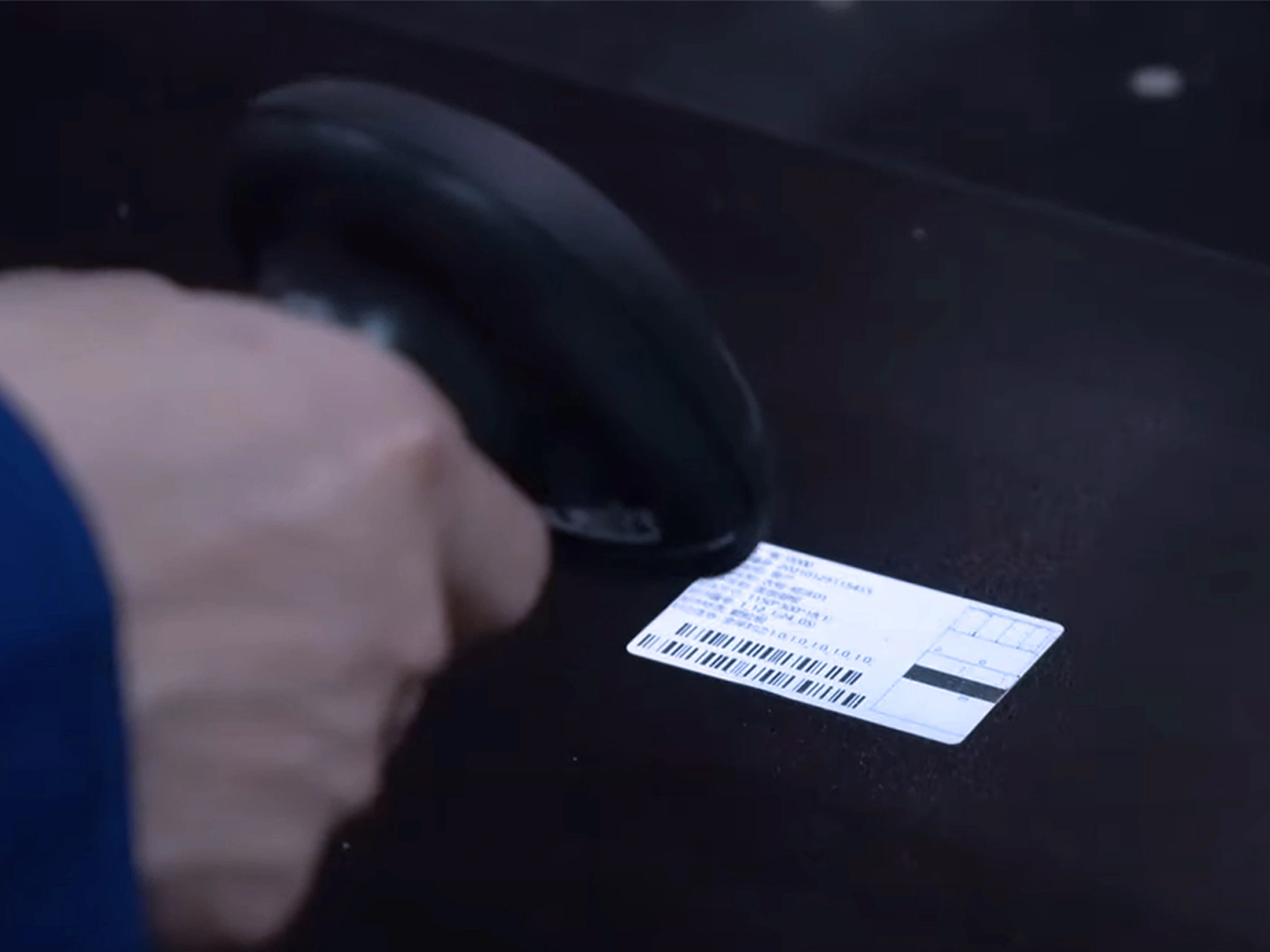

| Barcode Scanner | Included |

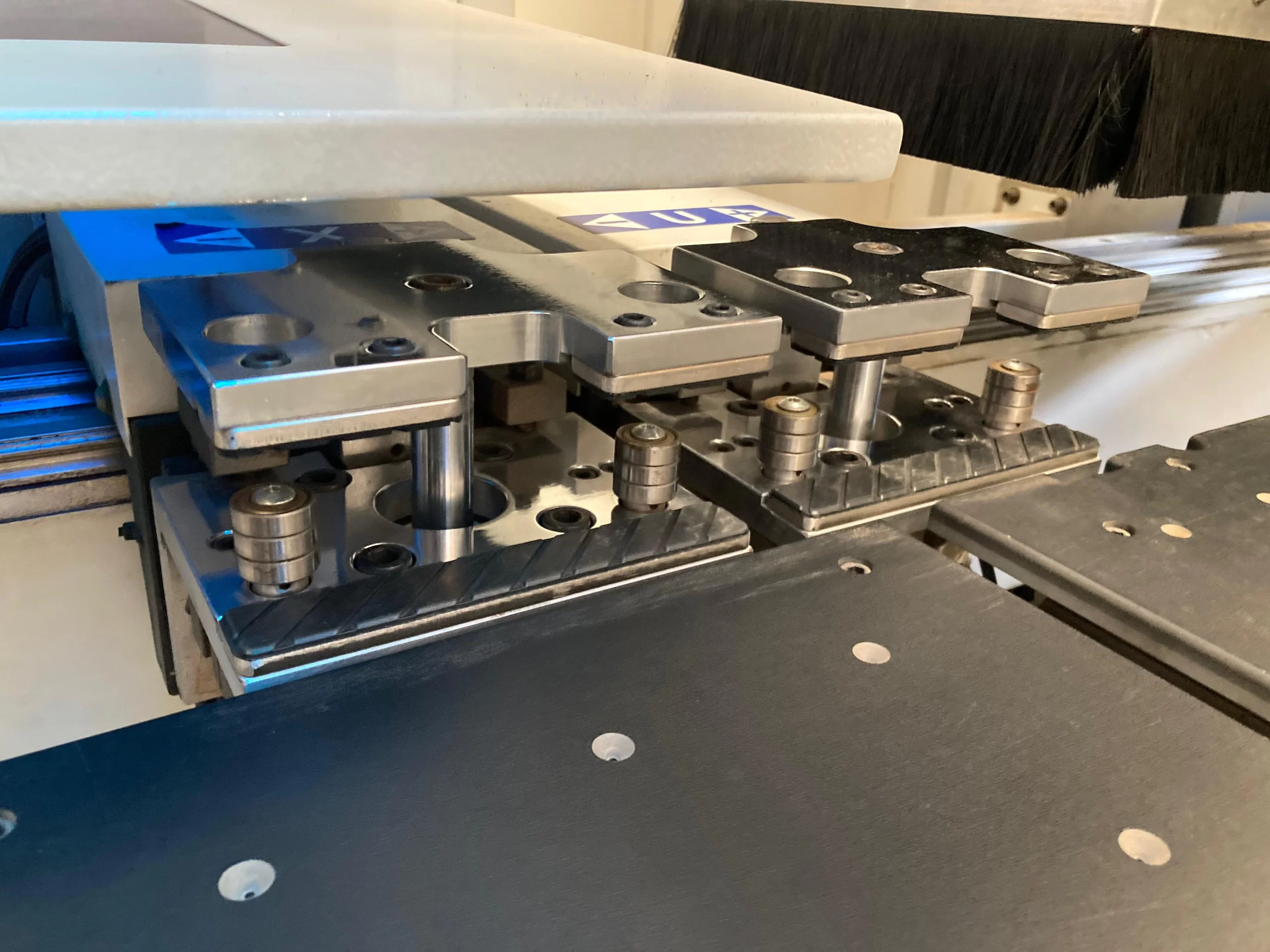

| Vacuum Table & Clamps | Yes |

| Output | 70–120 panels/hour (depending on layout) |

Boosts productivity with fast, automatic switching of multiple tools without operator interruption.

Sliding Panel Saw Machines – for accurate board cutting

Automatic Edge Banding Machines – for flawless edge sealing

CNC Router Machines – for advanced shaping and carving

Contact No:+91 8320070618

Website : www.umaboy.com

621, GIDC Estate, B/H Cifet, Phase IV, Vatva GIDC

Ahmedabad – 382445, Gujarat, India