AUTOMATIC EDGEBANDER

UEB 310 C Automatic Edge Bander Machine - Automatic Edge Banding Machine for Precise Panel Finishing

- SPECIFICATION

Basic Functions of UEB 310 C Automatic Edge Bander Machine

The UEB 310 C Automatic Edge Bander Machine is a compact and powerful automatic edge banding machine built to deliver seamless edge finishing on MDF, particle board, plywood, and laminated panels. Designed for modular furniture manufacturers, this machine offers unmatched accuracy, fast operation, and low maintenance in a budget-friendly package.

Whether you’re running a medium-scale woodworking factory or a high-volume modular furniture line, the UEB 310 C offers consistent output with minimal operator intervention.

PRODUCT IMAGES

Technical Specifications of UEB 310 C Automatic Edge Bander Machine

| Specification | Value |

| Model | UEB 310 C |

| Functions | Automatic Edge Banding |

| Feeding Speed | 18 m/min |

| Total Power | 8 kW |

| Phase | 3 Phase |

| Edge Tape Thickness | 0.4 – 3 mm |

| Machine Dimensions (L x W x H) | 5400 x 1600 x 1000 mm |

| Suitable Materials | MDF, Plywood, Particle Boards |

| Edge Tape Type | PVC, ABS, Veneer |

| Automation Level | Fully Automatic |

HIGHLIGHTS OF UEB 310 C Automatic Edge Bander Machine

Glue Unit

- Apply hot melt glue evenly on the panel’s vertical edges, pneumatically cut PVC edge banding to the panel’s length, and glue the entire surface of the panel height for a seamless finish.

- These features are specially designed to ensure a consistently precise finish and superior quality and to avoid any poor quality and Inconsistency of glue.

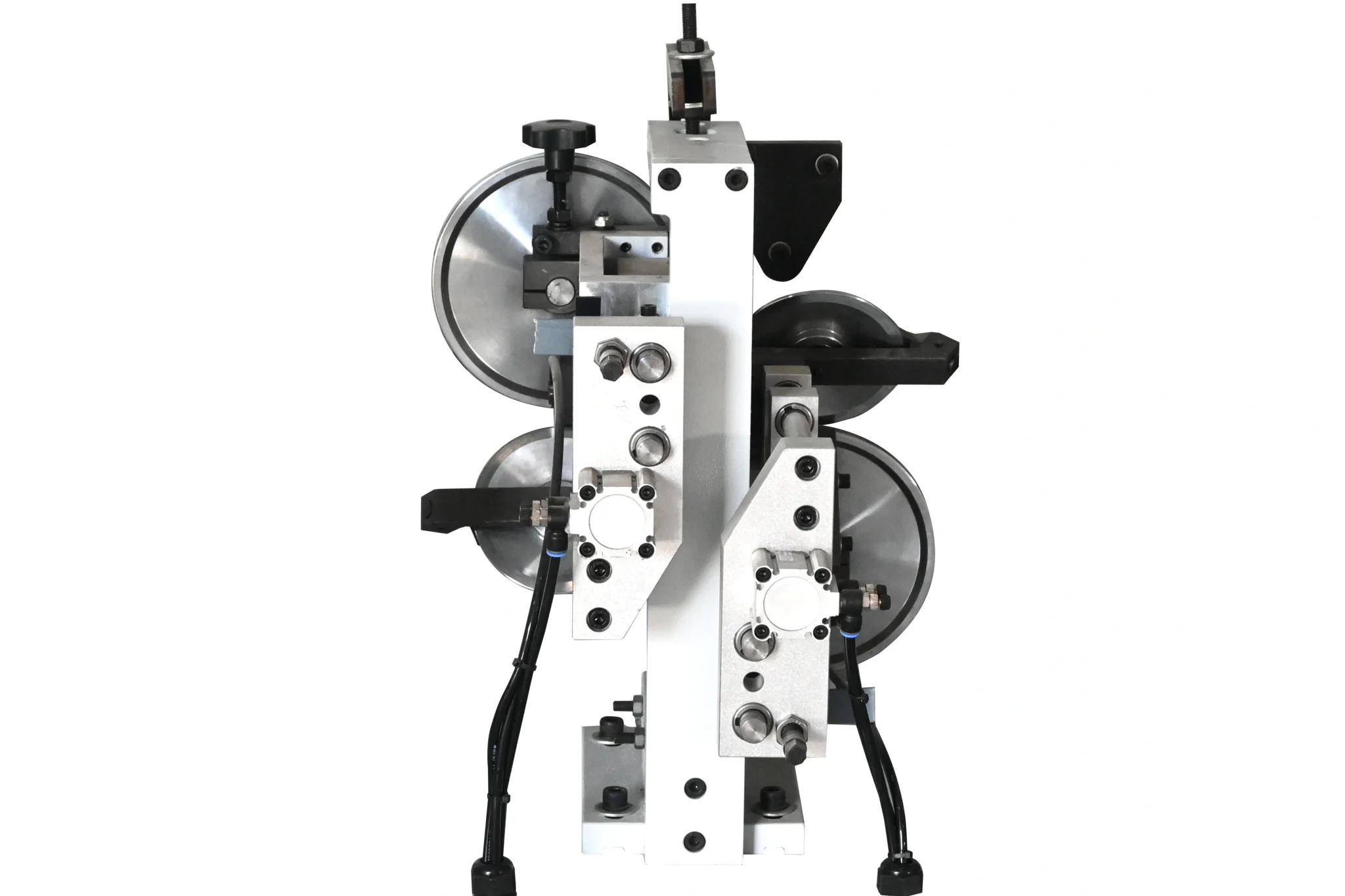

Pressure roller group

- A pressure roller group consists of 4 pressure rollers. The first pressure roller diameter is 150 mm and the remaining pressure roller diameters are 100 mm.

- The pressure rollers apply sufficient force to the panel to ensure that the glue adheres correctly and in the desired amount.

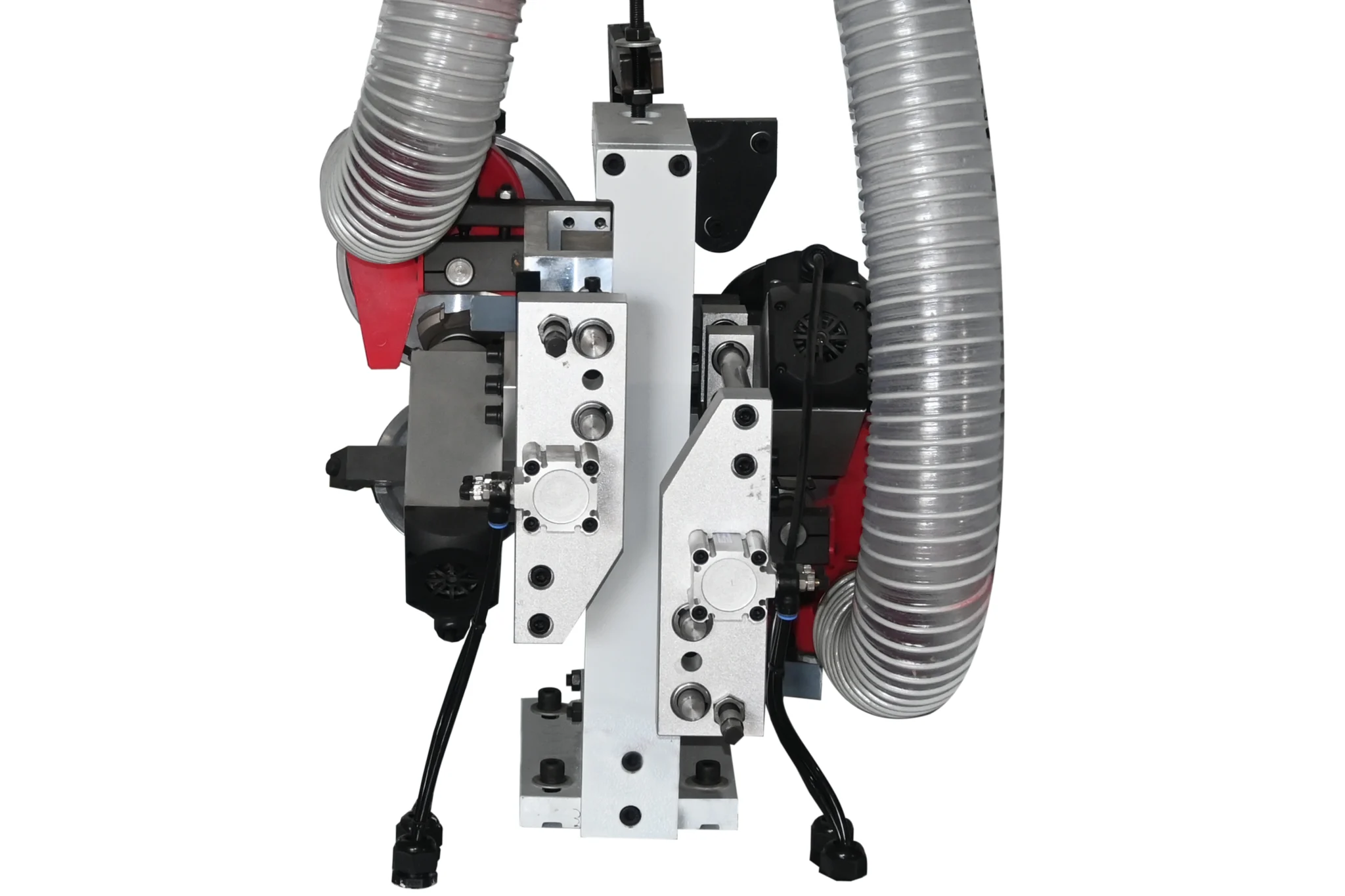

End cutting

- The unit is designed to trim excess PVC from both ends of the panel, featuring high-frequency motors with 0.55 kW power and 12,000 rpm. It is equipped with 150 mm diameter saw blades for precise and efficient cutting.

This process guarantees a flawless edge finish, delivering a perfect and professional final appearance.

Fine Top/Bottom Trimming

- It performs precise trimming of the top and bottom edges of the PVC edge banding for a seamless finish.

- Equipped with two high-performance frequency motors, a suction hood, and a vertical guide plate for enhanced precision and efficiency.

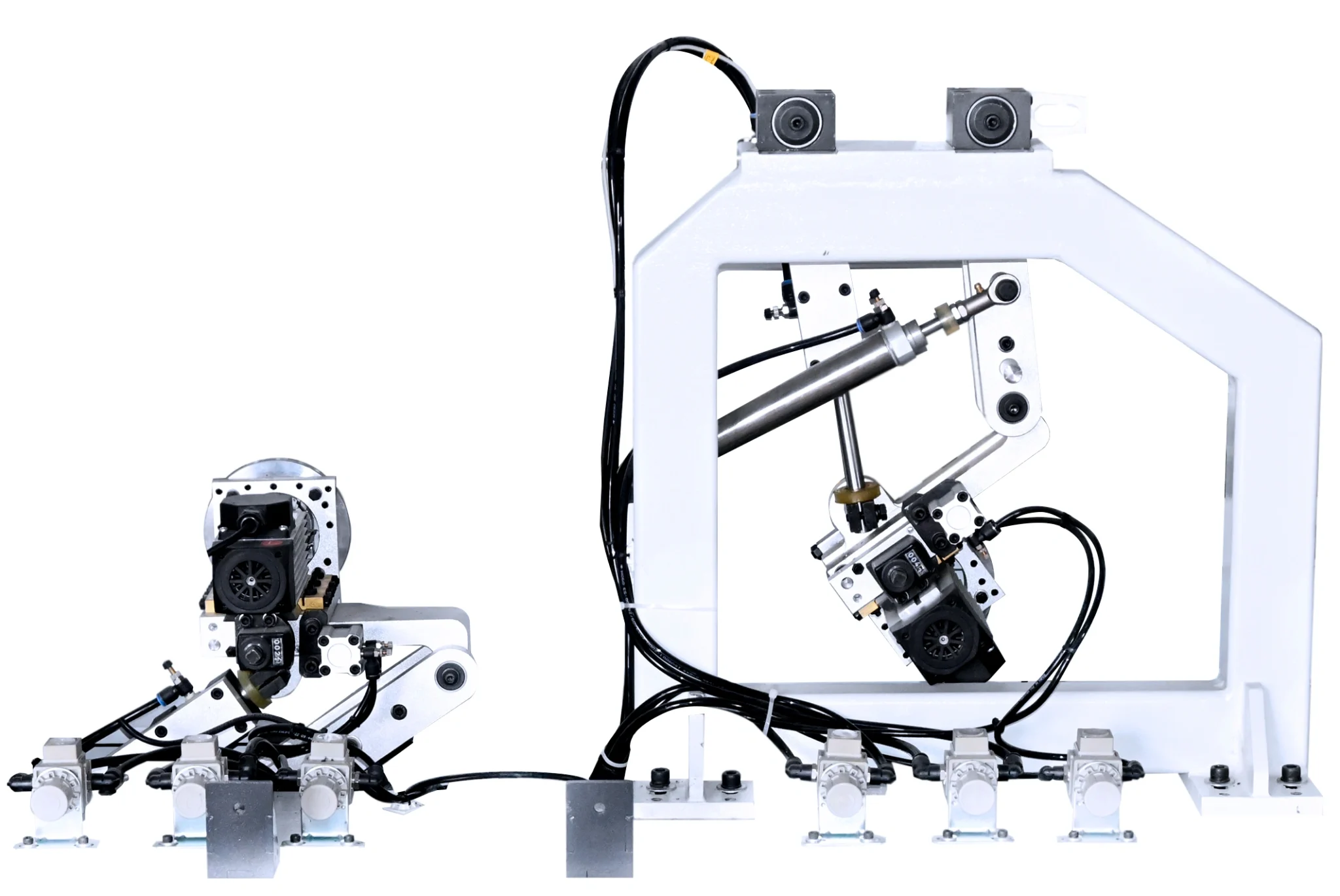

Corner Rounding

The corner rounding unit ensures precise trimming of the front and rear edges, delivering a perfect, smooth corner finish.

- Thanks to its movement along the panel edge using linear guideways and a pneumatic cylinder, the unit ensures optimal precision. This design delivers the best results for corner trimming, achieving a flawless finish.

PVC Scraping unit

PVC scrapping efficiently removes excess material from the top and bottom edges for a clean, smooth finish.

Includes two R-profile blades, a suction hood, and both front and vertical guide plates for precise and efficient edge trimming.

Liquid Spraying

- Spraying anti-adhesive liquid on the panel before the buffing unit ensures a clean and smooth finished surface. This process effectively prevents residue buildup, enhancing the overall finish quality.

- This process thoroughly cleans the treated area, leaving it with a rich, polished, and well-groomed appearance.

Buffing unit

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

UEB 310 C Automatic Edge Bander Machine - Built for Long-Term Performance

Heavy-duty steel body with vibration resistance for durability and stability

Energy-efficient design with smart motor control and low maintenance requirements

Emergency stop & pressure alarm system for operator safety

Ideal for modular furniture manufacturers, workshops, and panel processing units

Have Any Question ?

WE ARE HAPPY TO HELP !

For expanded production needs, explore Umaboy’s full range of woodworking solutions:

UEB 240 S Edge Bander – Best for small to mid-size workshops

UEB 540 PC Edge Bander – High-speed solution with advanced units

Sliding Panel Saw 3200 A++ – Perfect for precision board cutting

Automatic Beam Saw UBS 2800 Auto – Industrial-grade panel sizing

Or view all products in our Modular Machinery section.