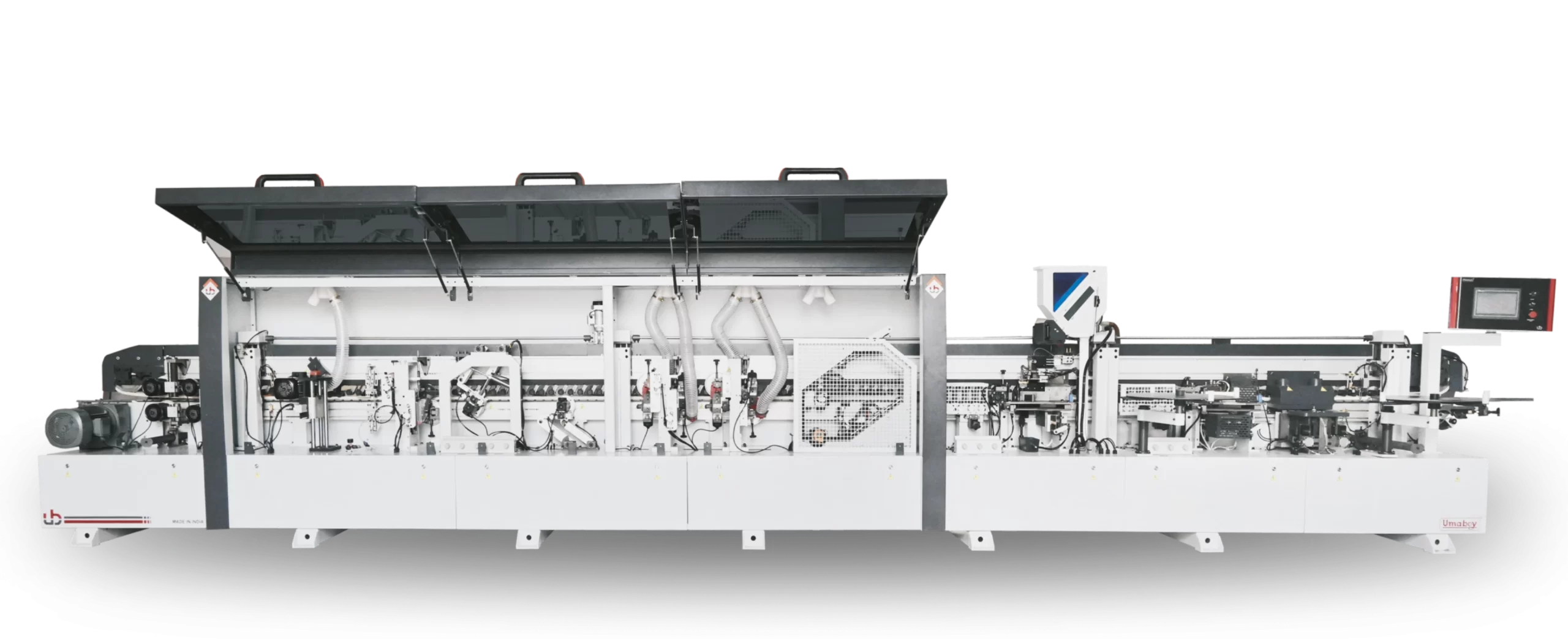

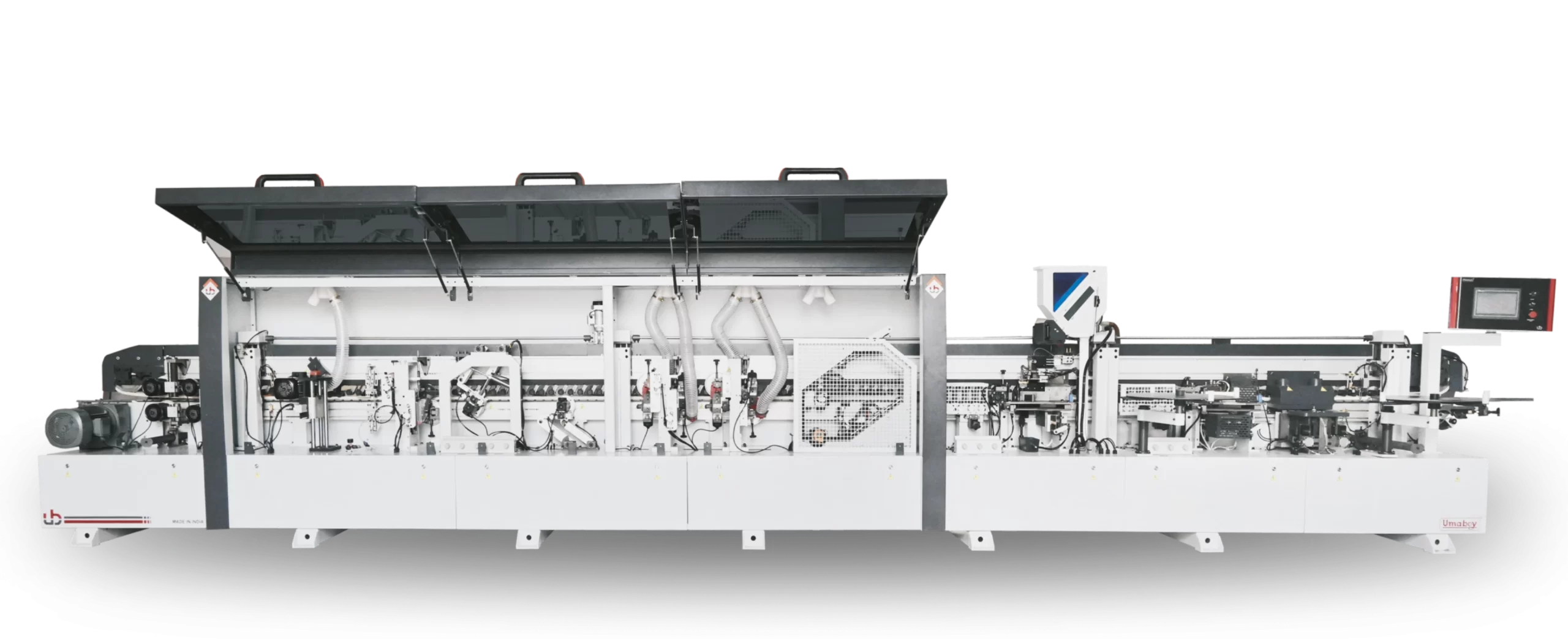

highspeed AUTOMATIC EDGEBANDER

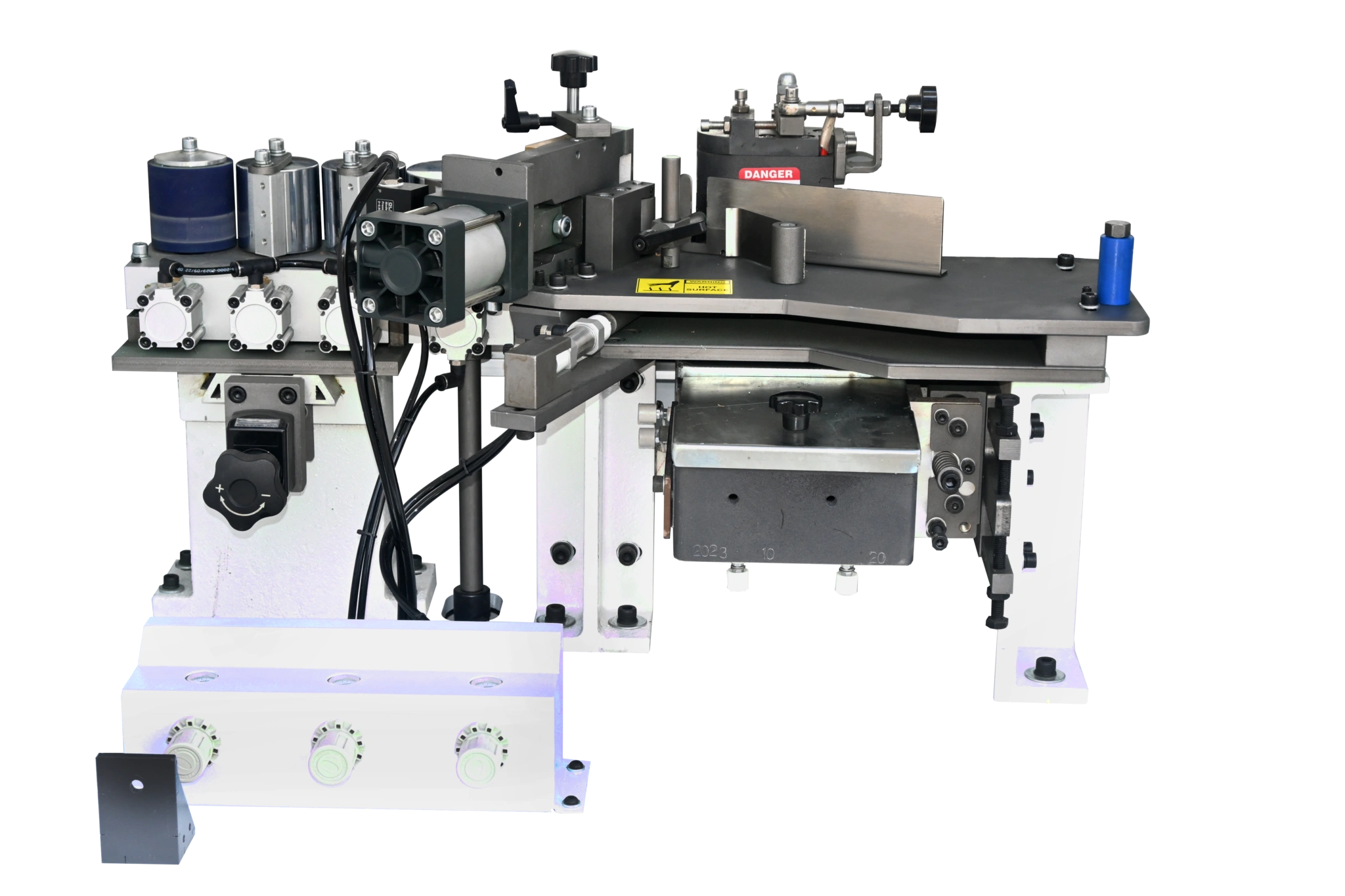

Auto Edge Banding Machine UEB 990 PUR

- SPECIFICATION

Basic Function of Auto Edge Banding Machine UEB 990 PUR

The Auto Edge Banding Machine UEB 990 PUR is the ultimate solution for manufacturers seeking flawless edge finishes with the power of PUR (Polyurethane Reactive) glue technology. This high-performance machine combines speed, accuracy, and durability—making it ideal for modular furniture, kitchen cabinets, wardrobes, and more.

With a maximum conveyor speed of 23 m/min and an intelligent configuration of trimming and corner rounding units, this machine is built to handle continuous production cycles while maintaining top-tier finishing quality on every panel edge.

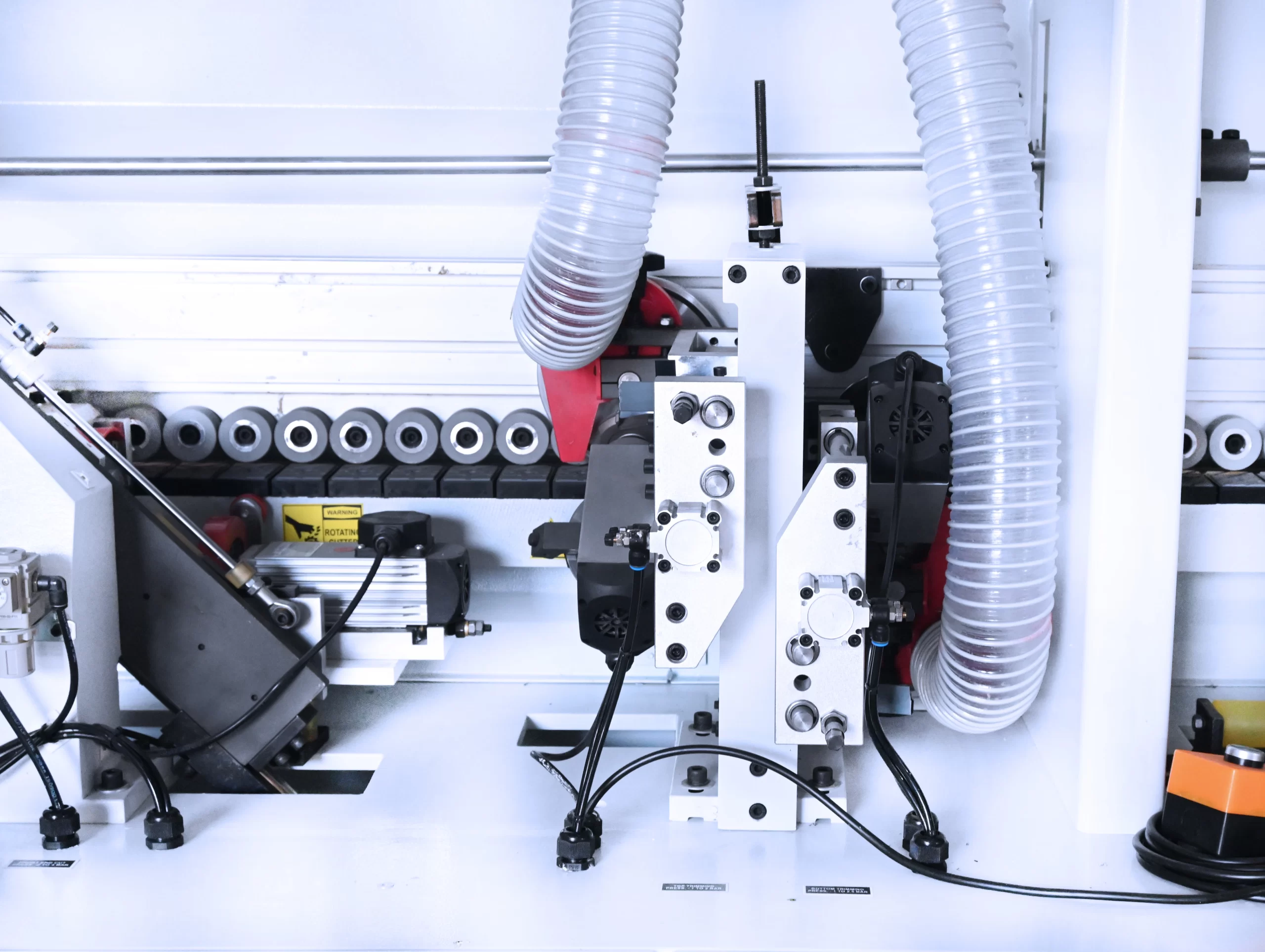

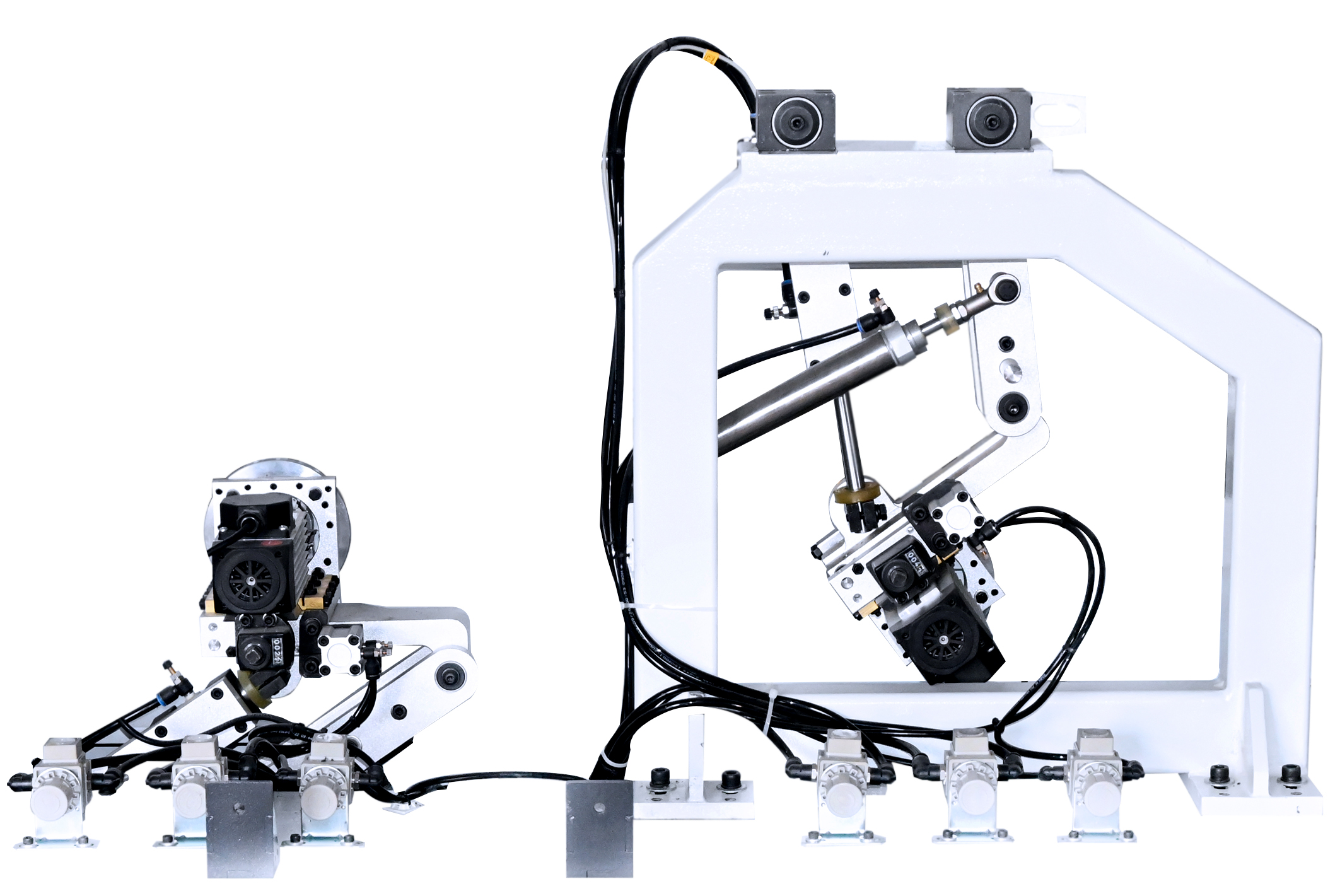

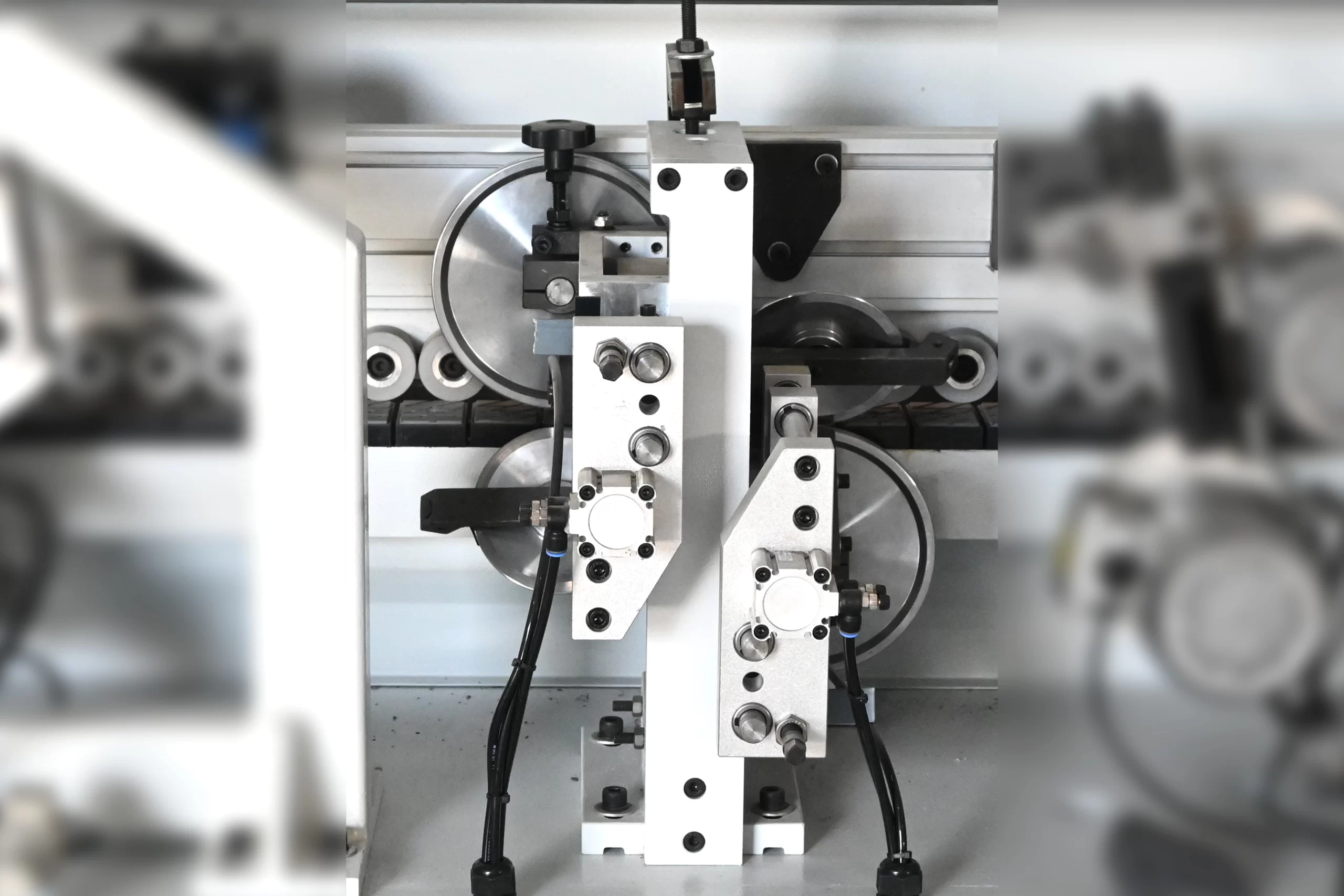

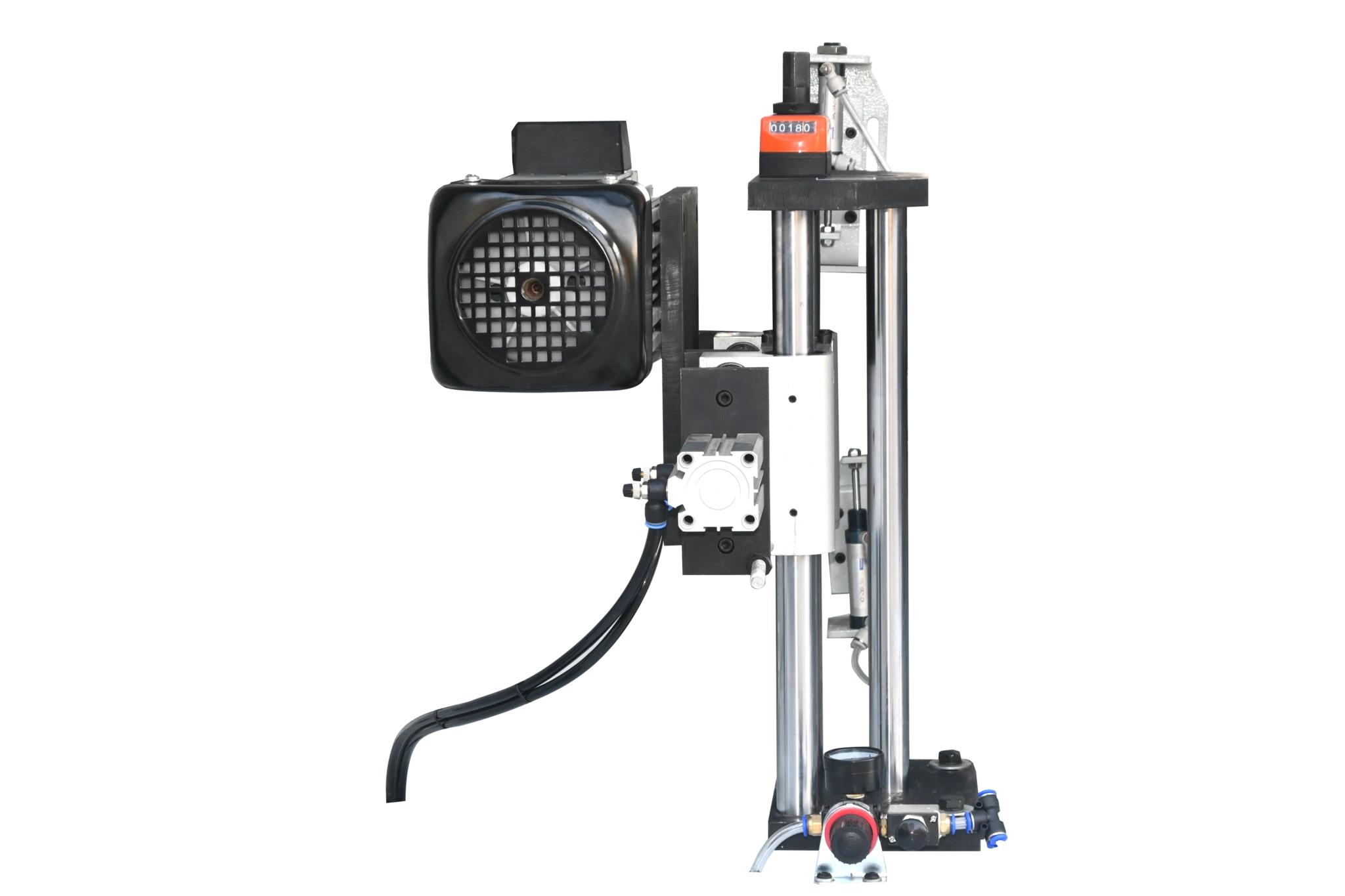

Auto Edge Banding Machine UEB 990 PUR IMAGES

Technical Specifications of Auto Edge Banding Machine UEB 990 PUR

| Specification | Details |

| Model | UEB 990 PUR |

| Electric Level | 415-220V / 50 Hz |

| Edge Material Thickness | 0.4 – 3 mm |

| Panel Thickness | 10 – 60 mm |

| Min. Width of Panel | 50 mm |

| Min. Length of Panel | 120 mm |

| Conveyor Speed | 14 / 18 / 23 m/min |

| Conveyor Thickness Adjustment | Electric |

| Conveyor Up/Down | 0.37 kW |

| Total Electric Power | 30 kW |

| Total Air Pressure | 6 – 8 bars |

| Pre-Milling Motor Power | 2 × 2.2 kW |

| End Cutting Unit Power | 2 × 0.55 kW |

| Top/Bottom Fine-Trimming Power | 2 × 0.55 kW |

| Top/Bottom Rough-Trimming Power | 2 × 0.55 kW |

| Corner Rounding Unit Power | 2 × 0.3 kW |

| Grooving Unit Motor Power | 4 kW |

| Max Depth of Grooving | 17 mm + 9 mm blade |

| 1st Buffing Unit Power | 2 × 0.37 kW |

Auto Edge Banding Machine UEB 990 PUR HIGHLIGHTS

Liquid Sprayer

- Spraying anti adhesive liquid on panel will restrict the glue on top and bottom surface of panel.

- Equipped with PLC controlled pneumatic flow.

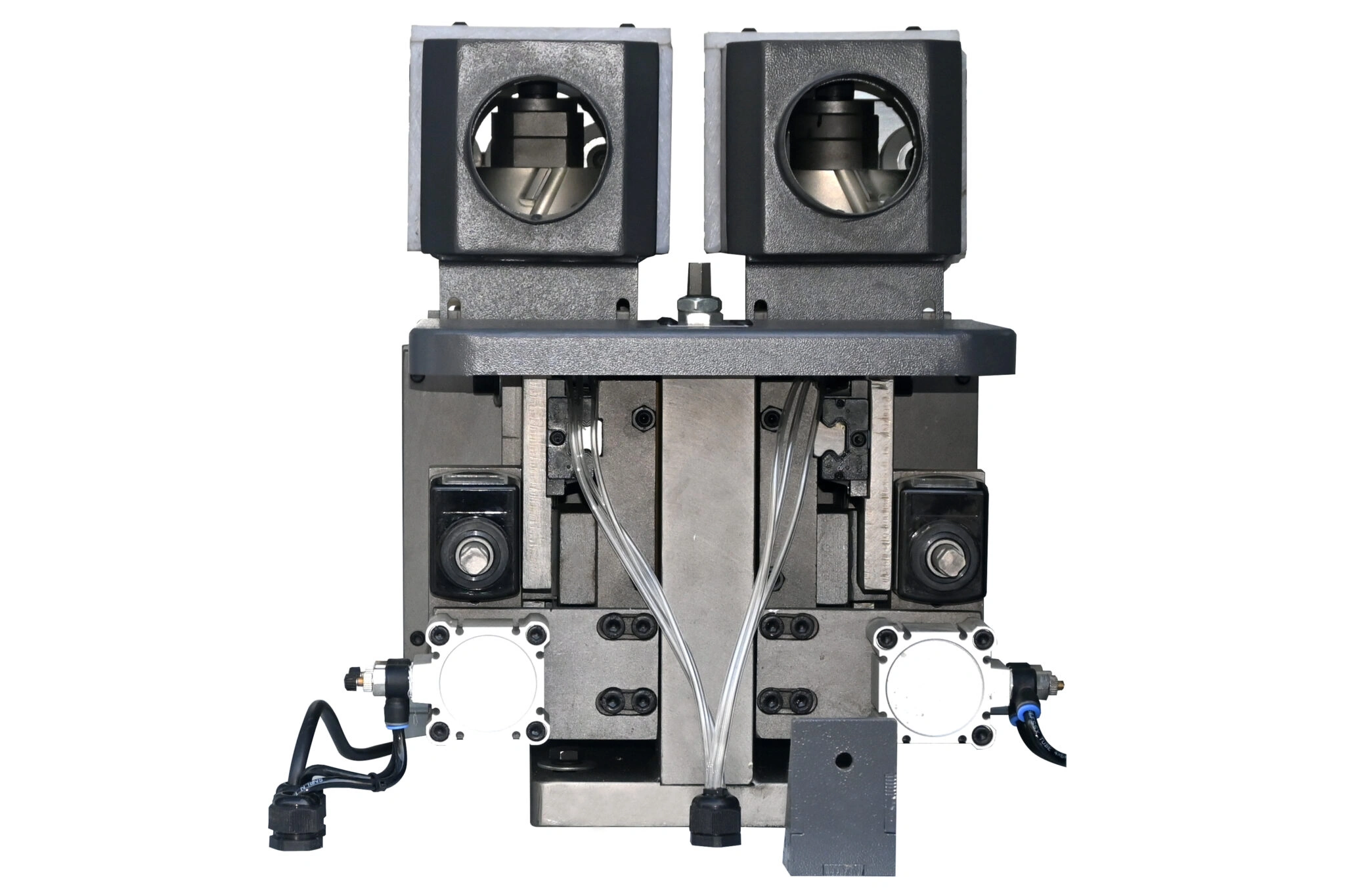

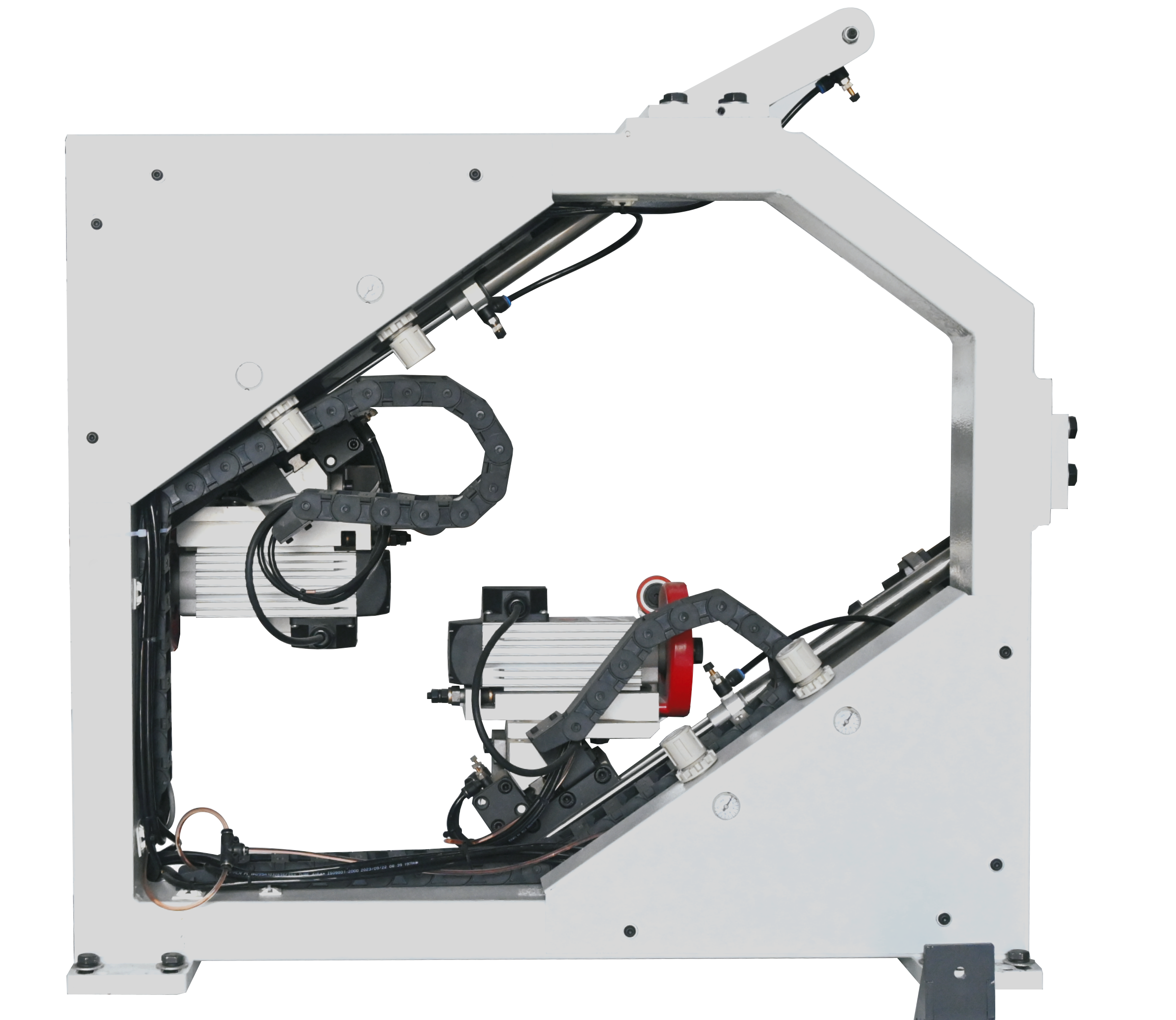

Premilling Unit

- An automatic length sensor switch is installed, which allows accurate determination of panel length and processing of the entire panel.

- Equipped with a 1.5 KW spindle motor-powered, 12000 RPM diamond cutter head.

- There is a partition and an air blower installed between the Premilling Unit and the Glue Unit.

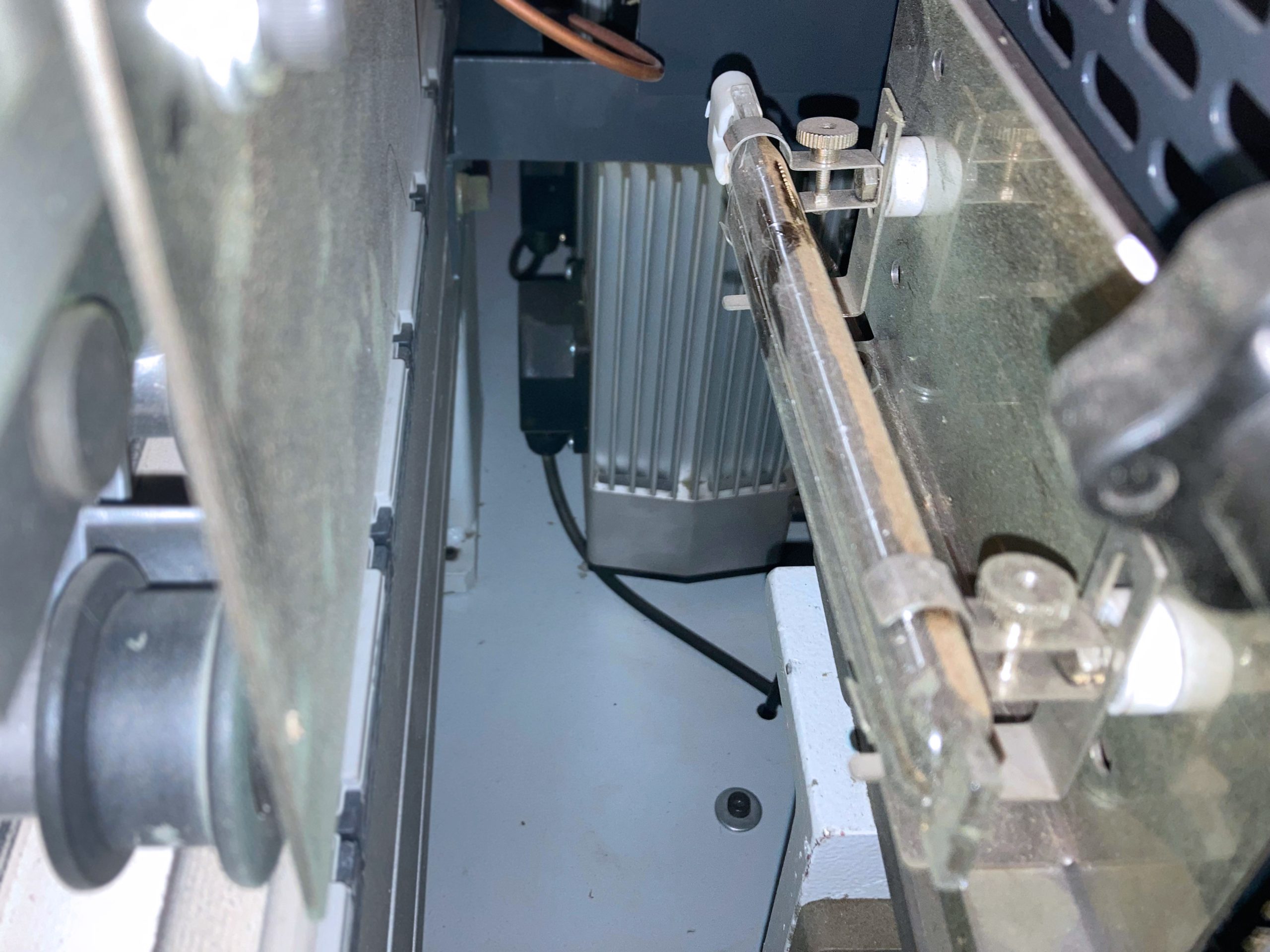

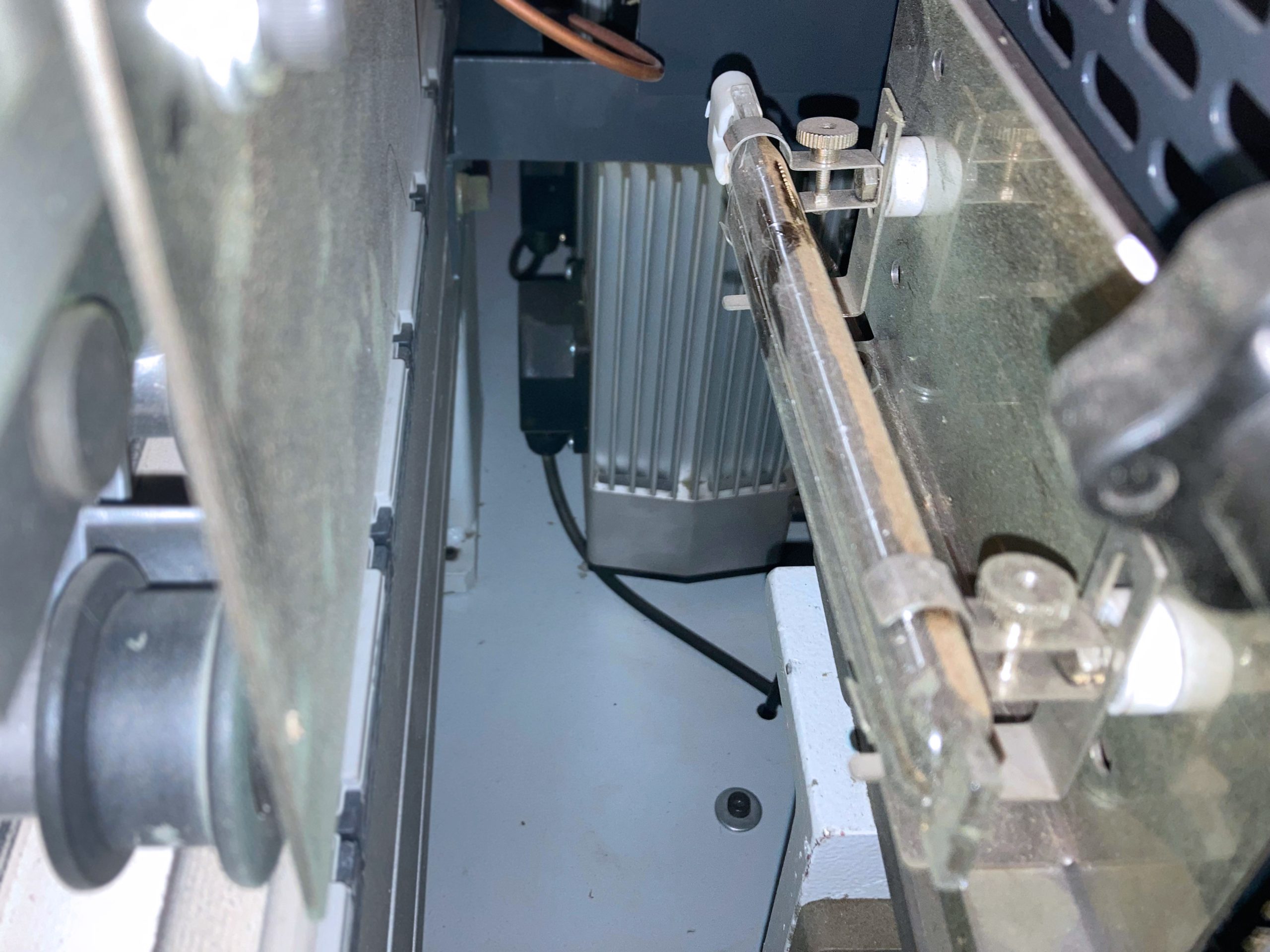

Heating Lamp

- This function is used to remove moisture from the edge of the panel.

- Help to get perfect bonding during edge banding

Glue unit

- Apply the hot melt glue on the panel, pneumatic cutting of PVC edge banding as per the length of the panel, gluing on the entire surface of the panel height.

- These features are specially designed to ensure a consistently precise finish and superior quality and to avoid any poor quality and inconsistency of glue.

Pressure roller group

- A pressure roller group consists of 4 pressure rollers. The first pressure roller diameter is 150 mm and the remaining pressure roller diameters are 100 mm.

- It offers incredible results with a smooth finish and a long-lasting edge attached to the panel.

- On the glue table, all pressure roller are mounted 1 degree tilted to each other side . This ensures that the glue is evenly and firmly distributed in the centre of the panel. It also prevents access overflow of glue on the panel surface.

Heating Lamp

- This function is used to remove moisture from the edge of thw panel.

- Help to get perfect bonding during edge banding

Pre-melting glue unit

- Glue is always there in liquid form in the upper pot.

- It will pour the glue as per requirement.

- Cable sensor helps to maintain glue level in bottom pot.

Pressure roller group

- A pressure roller group consists of 4 pressure rollers. The first pressure roller diameter is 150 mm and the remaining pressure roller diameters are 100 mm.

- It offers incredible results with a smooth finish and a long-lasting edge attached to the panel.

Double rail end cutting unit

- Unit used to cut excess PVC from both ends of the panel. Equipped with high-frequency motors with a power of 0.55 kW and 12,000 rpm and saw blades with a diameter of 150 mm.

- High reliability and precision as installed large linear guides. 2 saw blades diam. 104 x 3.0 x 22 mm, T = 30.

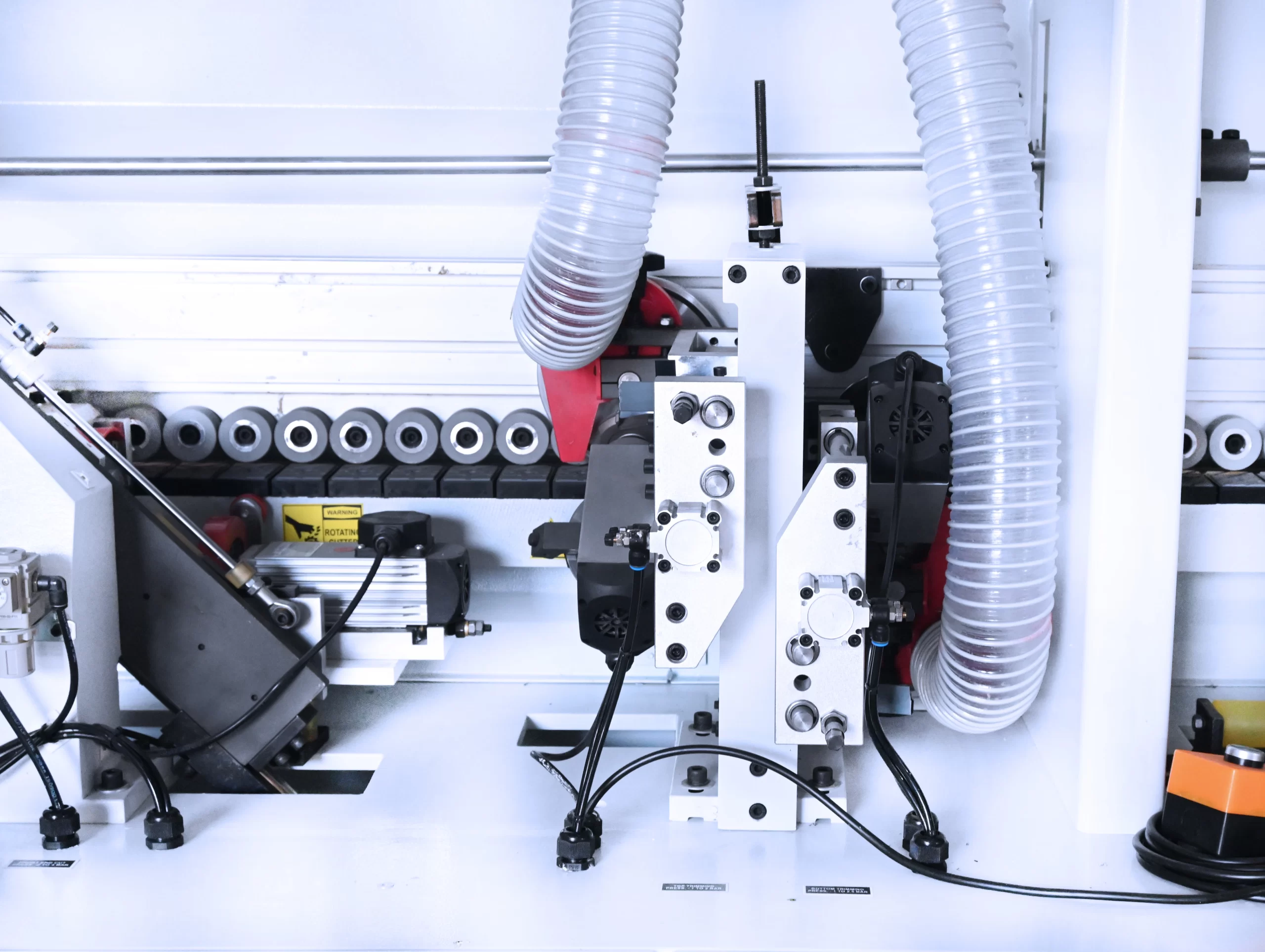

Rough top/bottom trimming

- Perform Initial trimming of the top and bottom edges of the glued edge.

- Comes with 2 high end frequency motors with suction hood and front and vertical Guide Plate

- All spindles equipped with encoder readouts for fast adjustment

Fine top/bottom trimming

- Performs fine trimming of the top and bottom edges of the pvc edge.

- Comes with 2 highend frequency motors with suction hood and vertical Guide Plate.

- Motors manually tiltable between 2 working positions: Flat and radius trimming.

Corner Rounding

- corner rounding unit for front and rear edges for perfect corner trimming.

- This unit works in different profile in prosessed post forming machine like half nose, full nose, and duck nose.

- Workpiece length min – 150 mm, edgebanding thickness upto 0.4 mm to 3mm.

PVC Scrapping Unit

- PVC Scrapping to remove excess pvc from top and bottom edge.

- It provides better edge, consistency, precision and smoothness..

- Includes 2 R-profile blades with suction hood and front and vertical guide plate.

Glue Scraper

- The glue scraper helps remove excess adhesive from the joint surface of the panel and edgeband.

- This process ensures that there is no glue on the panel or outside the application area.

- Work as a soft scrapper which gives fine finishing.

Grooving Unit

- The built-in grooving function in the machine gives easy work for making a groove on the board.

- This function is PLC controlled, so it’s very easy to operate.

Liquid Sprayer

- Spraying anti-adhesive liquid on the panel before buffing the unit gives the clean finished surface.

- Equipped with PLC controlled pneumatic flow.

- Workpiece length min – 150 mm, edgebanding thickness up to 0.4 mm to 3 mm.

Buffing unit

- Edge banding machine buff wheels are used to polish and buff the edges of the top/bottom wood panels to create a smooth and glossy finish.

- Finishing the edge looks dimensional and attractive with this process.

Have Any Question ?

WE ARE HAPPY TO HELP !

Explore More Woodworking Machines From Umaboy

UEB 860 PC Edge Banding Machine – High-speed model with corner rounding

UEB 640 PCGD – Mid-size machine with groove cutter

UEB 310 C – Compact and efficient for basic edge banding

Sliding Panel Saw Machines – For precise board cutting