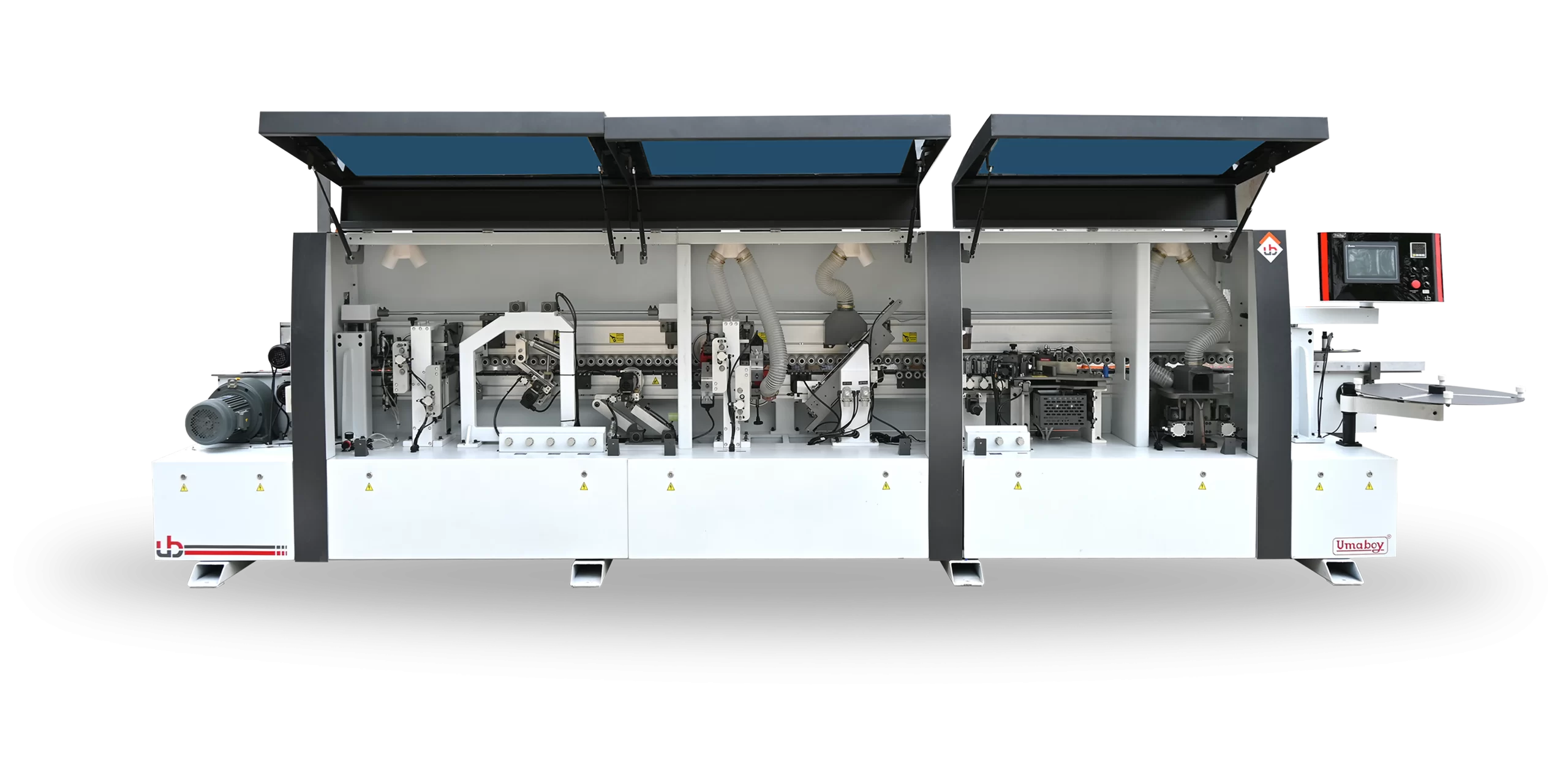

AUTOMATIC EDGEBANDER

Automatic Edge Bander UEB 860 PC

- SPECIFICATION

Basic Functions of Automatic Edge Bander UEB 860 PC

The Automatic Edge Banding Machine UEB 860 PC is built for high-performance edge processing in modular furniture manufacturing. With a robust structure, intelligent automation, and versatile speed options (14/18/23 m/min), this machine is engineered for both precision and mass production.

Whether you’re running a small factory or a large furniture manufacturing unit, the UEB 860 PC delivers premium edge finishing with less manpower and higher accuracy. From panel feeding to corner rounding, every function is designed to produce a smooth, ready-to-assemble product.

Technical Specifications of Automatic Edge Bander UEB 860 PC

| Specification | Details |

| Model | UEB 860 PC |

| Electric Level | 415-220/50 Hz |

| Edge Material Thickness | 0.4–3 mm |

| Panel Thickness | 10–60 mm |

| Minimum Width of Panel | 50 mm |

| Minimum Length of Panel | 120 mm |

| Conveyor Speed | 14/18/23 m/min |

| Conveyor Thickness Adjustment | Electric |

| Conveyor Up/Down | 0.37 kW |

| Total Electric Power | 18 kW |

| Total Air Pressure | 6–8 bars |

| Pre-Milling Motor Power | 2×2.2 kW |

| End Cutting Unit Power | 2×0.55 kW |

| Top/Bottom Fine Trimming Unit Power | 2×0.55 kW |

| Corner Rounding Unit Power | 2×0.3 kW |

| Max Grooving Depth | 17 mm + 9 mm Blade |

| Buffing Unit Power | 2×0.37 kW |

| Overall Size (L × W × H) | 6350 × 1600 × 1000 mm |

Automatic Edge Bander UEB 860 PC IMAGES

HIGHLIGHTS OF Automatic Edge Bander UEB 860 PC

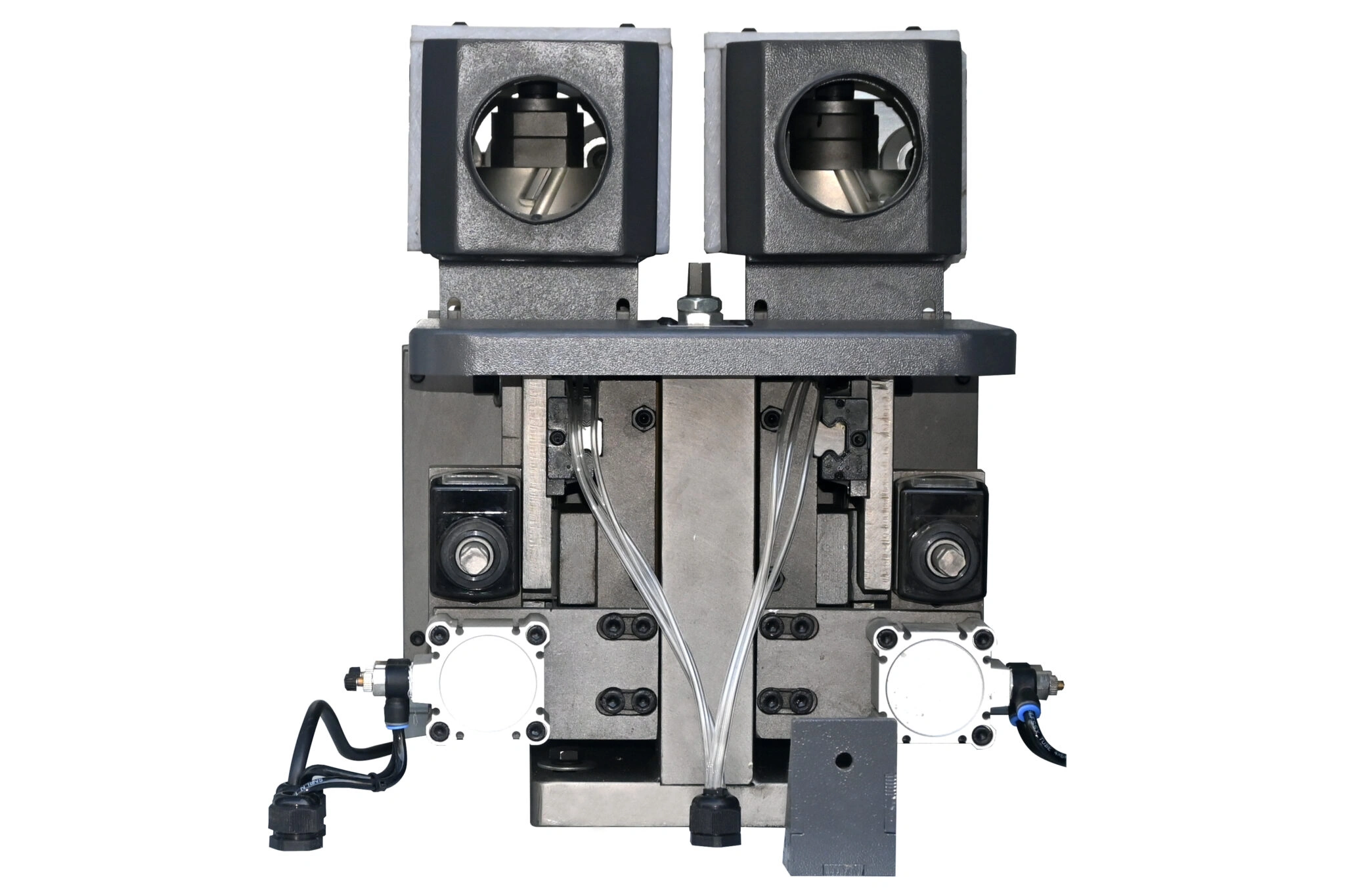

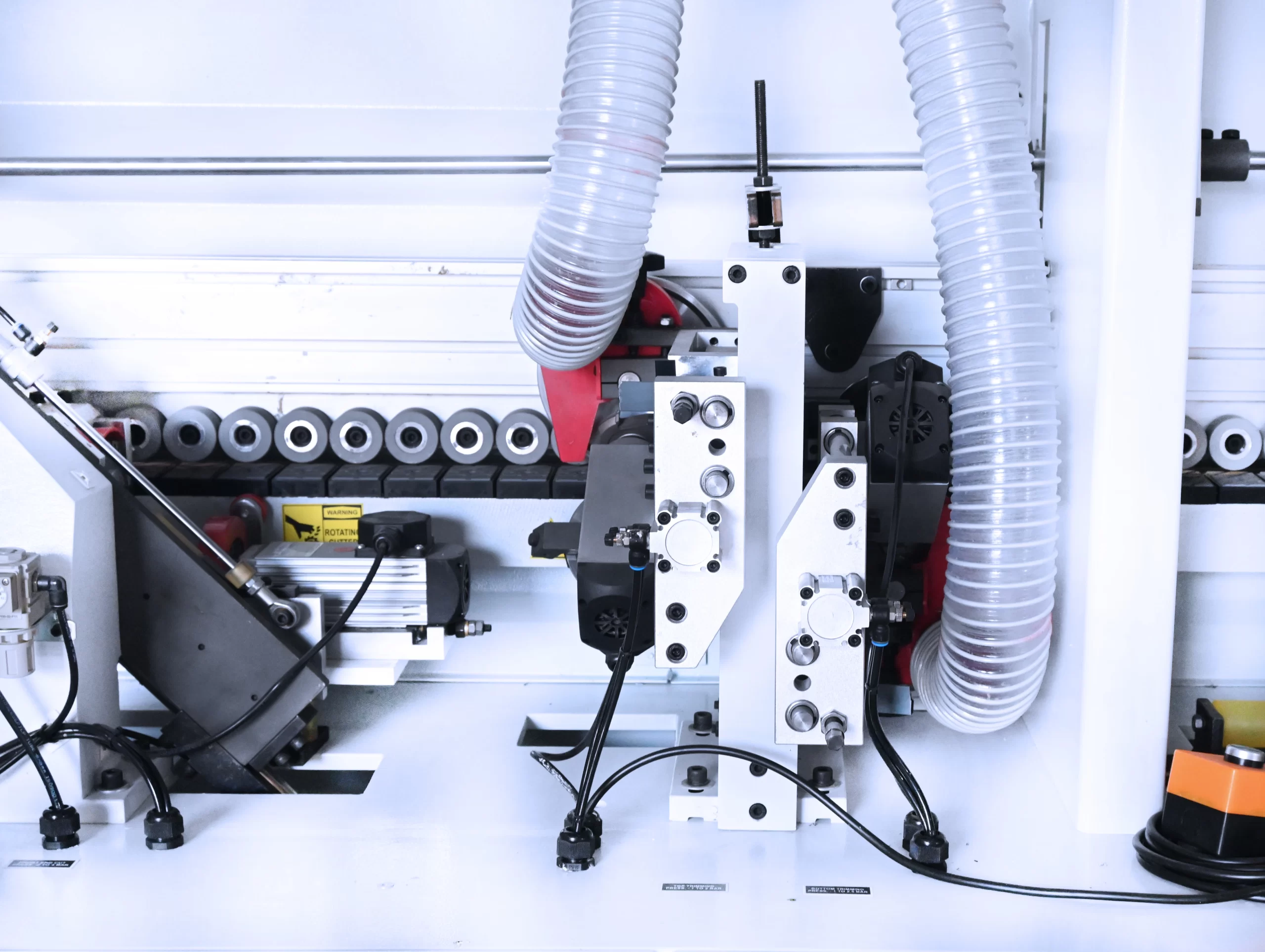

Premilling Unit

- An automatic length sensor switch is installed, which allows accurate determination of panel length and processing of the entire panel.

- Equipped with a 1.5 KW spindle motor-powered, 12000 RPM diamond cutter head.

- There is a partition and an air blower installed between the Premilling Unit and the Glue Unit.

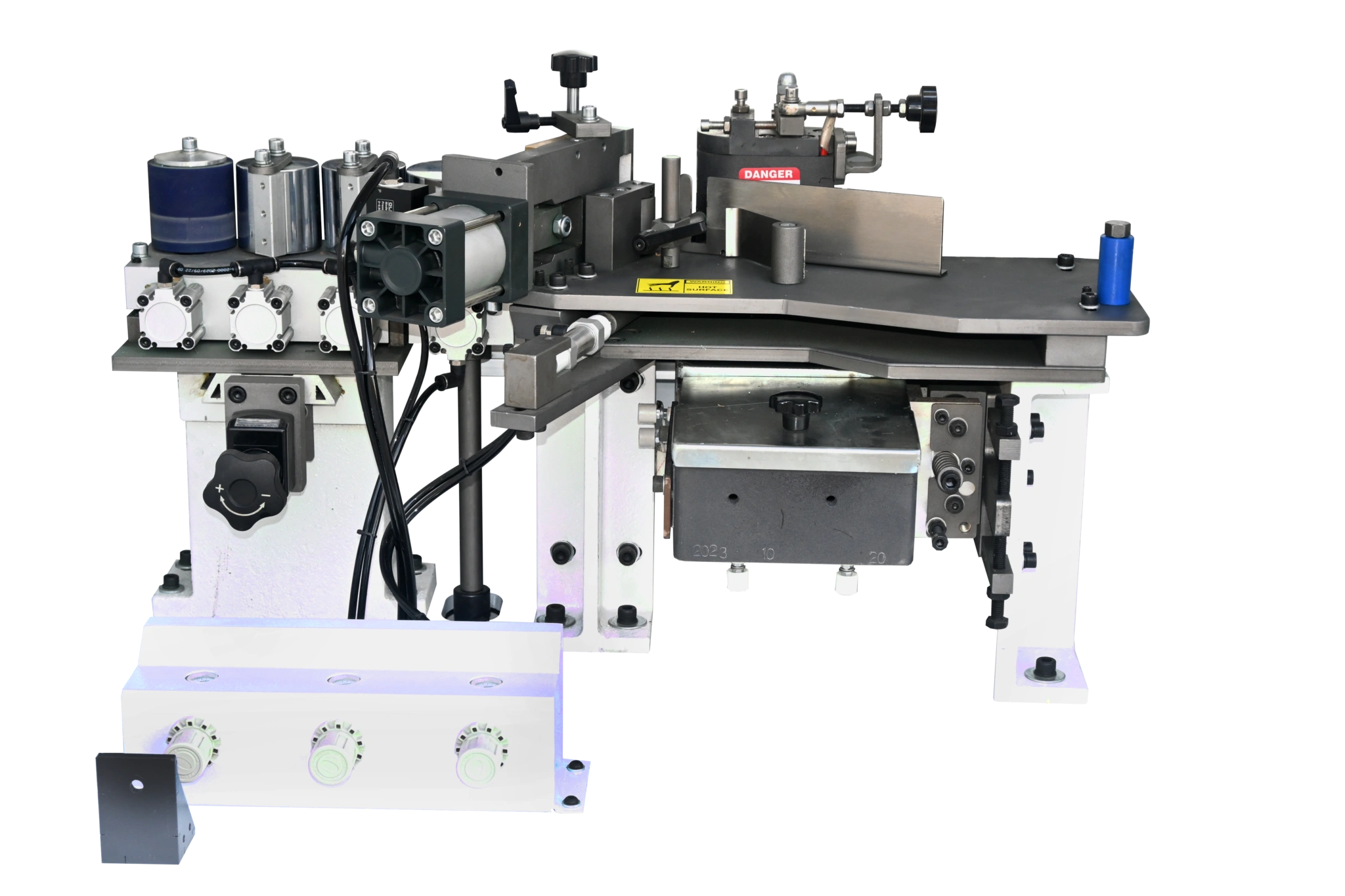

Glue unit

- Apply the hot melt glue on the panel, pneumatic cutting of PVC edge banding as per the length of the panel, gluing on the entire surface of the panel height.

- These features are specially designed to ensure a consistently precise finish and superior quality and to avoid any poor quality and inconsistency of glue.

Pressure rollel group

- A pressure roller group consists of 4 pressure rollers. The first pressure roller diameter is 150 mm and the remaining pressure roller diameters are 100 mm.

- It offers incredible results with a smooth finish and a long-lasting edge attached to the panel.

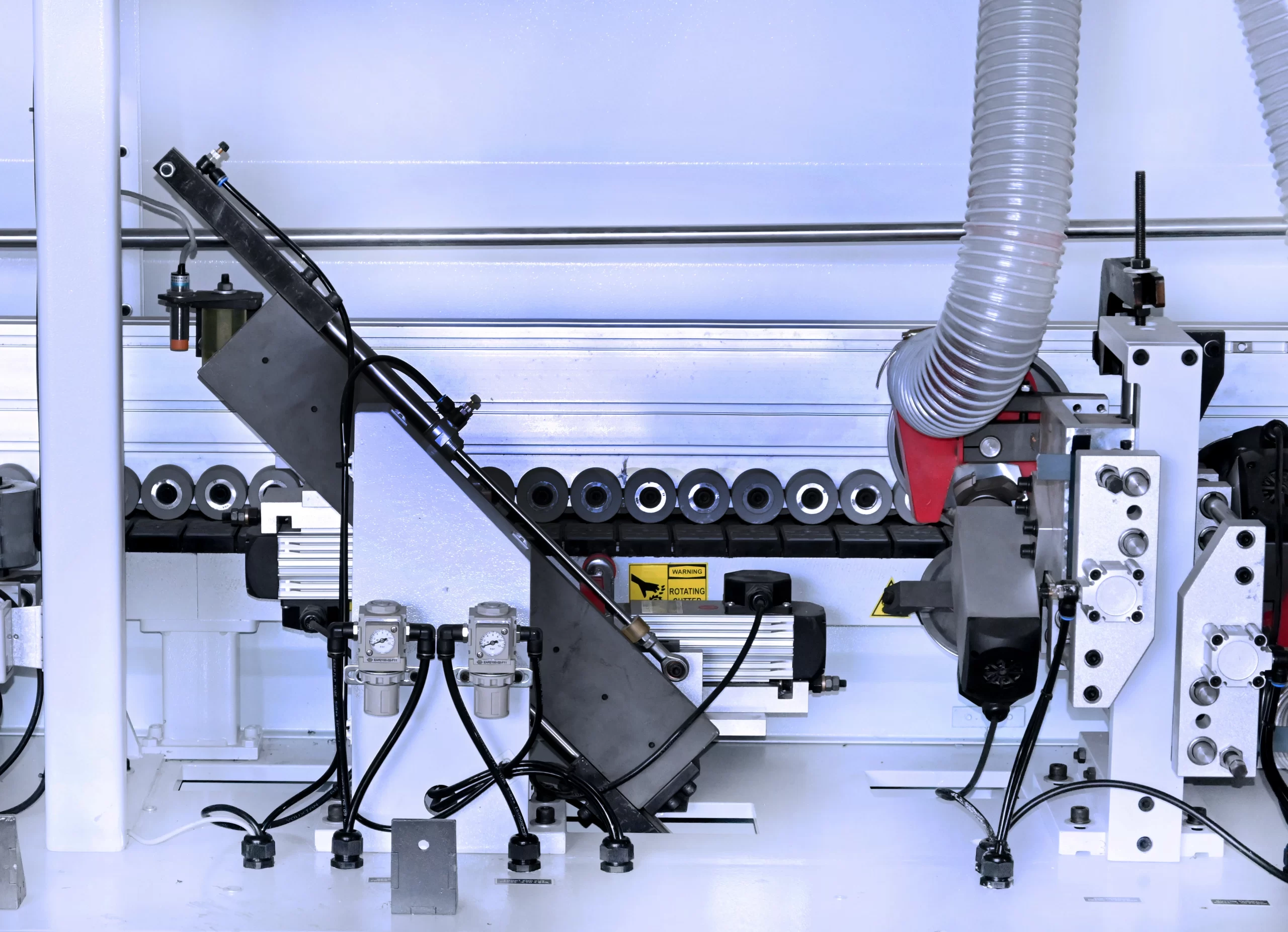

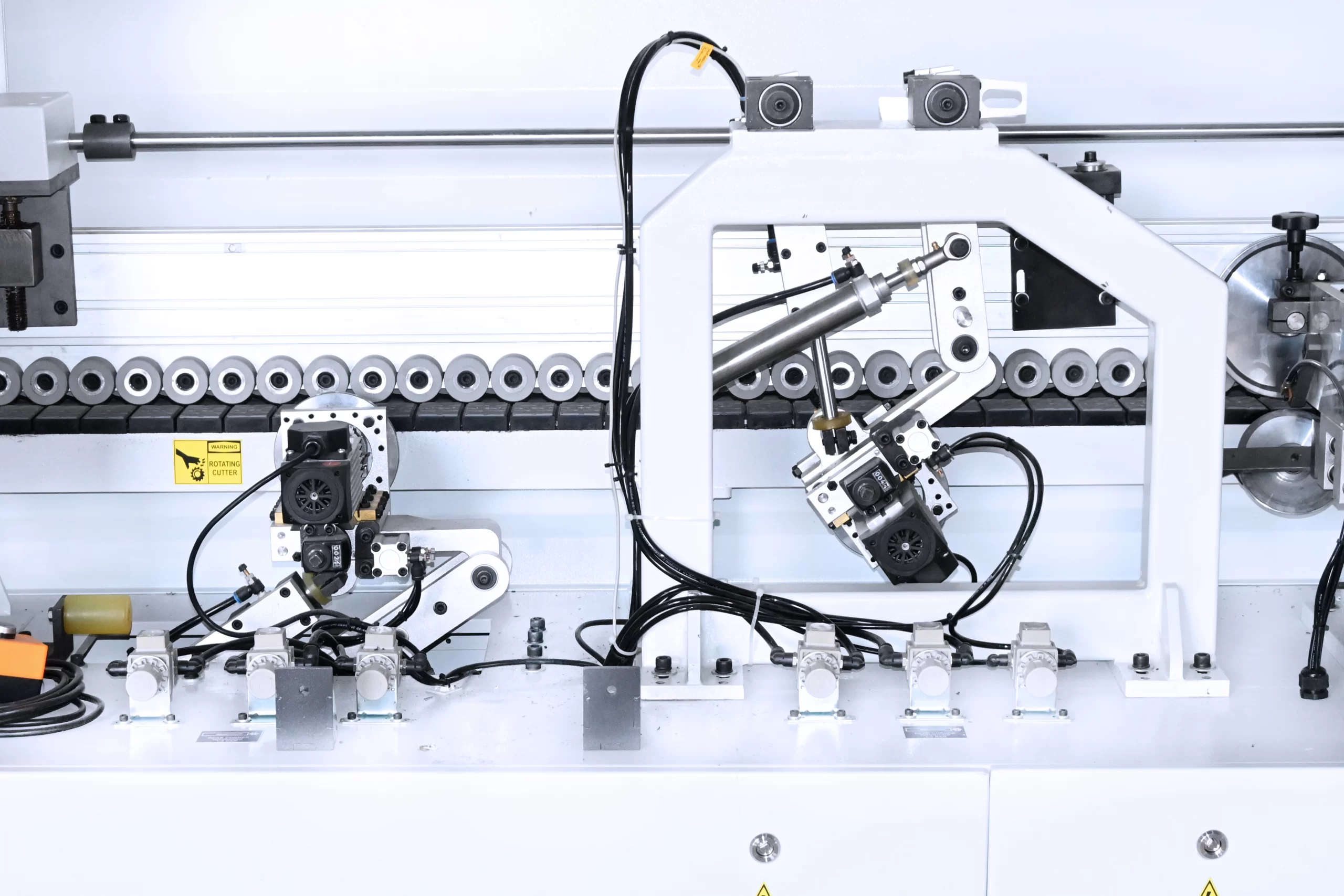

End Cutting unit

- Unit used to cut excess PVC from both ends of the panel. Equipped with high-frequency motors with a power of 0.55 kW and 12,000 rpm and saw blades with a diameter of 150 mm.

- This process ensures a precise edge finish for a perfect finished look.

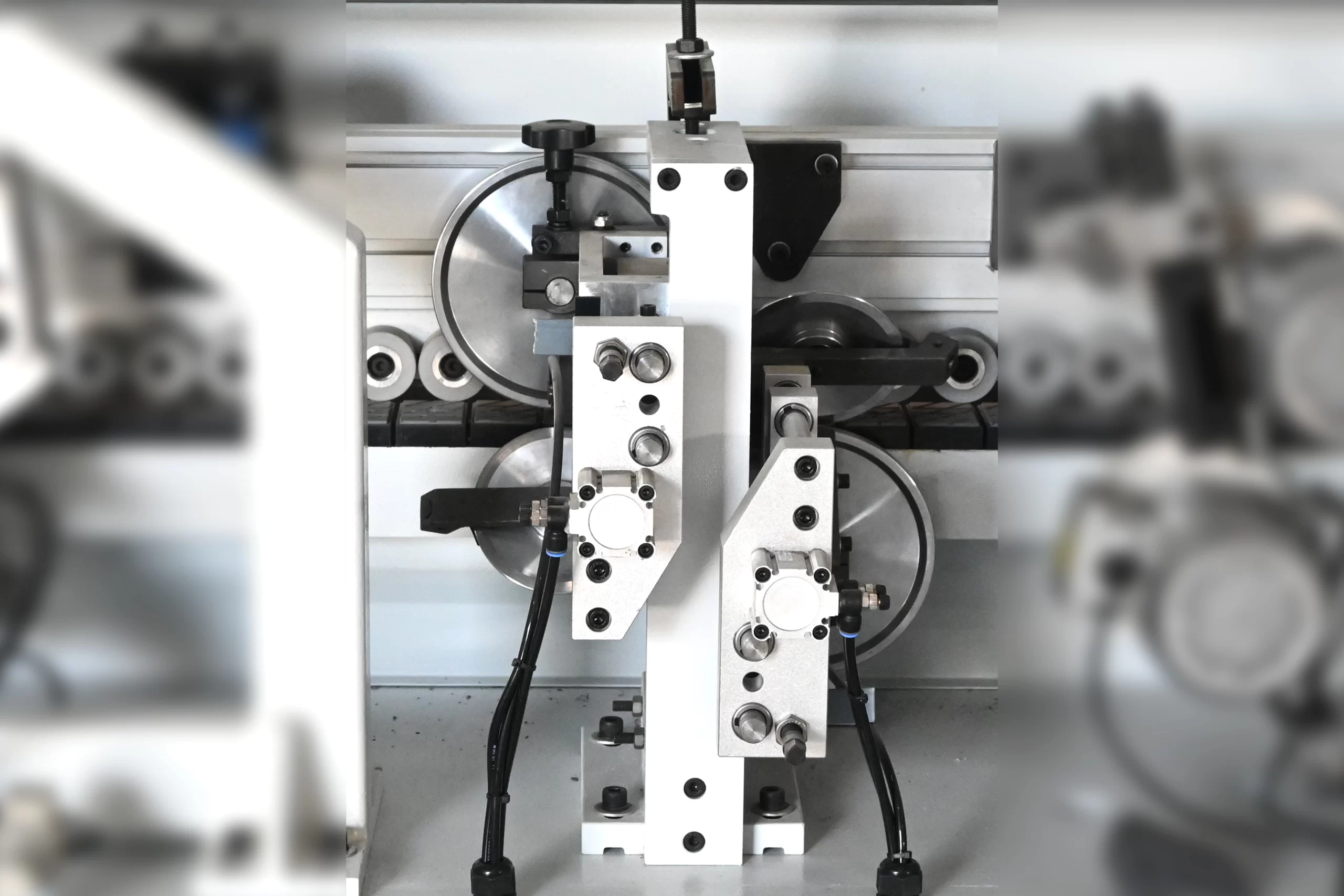

Fine top/bottom trimming

- Performs fine trimming of the top and bottom edges of the pvc edge.

- Comes with 2 highend frequency motors with suction hood and vertical Guide Plate.

- Motors manually tiltable between 2 working positions: Flat and radius trimming.

Corner Rounding

- corner rounding unit for front and rear edges for perfect corner trimming.

- This unit works in different profile in prosessed post forming machine like half nose, full nose, and duck nose.

- Workpiece length min – 150 mm, edgebanding thickness upto 0.4 mm to 3mm.

PVC Scrapping Unit

- PVC Scrapping to remove excess pvc from top and bottom edge.

- It provides better edge, consistency, precision and smoothness..

- Includes 2 R-profile blades with suction hood and front and vertical guide plate.

Glue Scraper

- The glue scraper helps remove excess adhesive from the joint surface of the panel and edgeband.

- This process ensures that there is no glue on the panel or outside the application area.

Liquid Sprayer

- Spraying anti-adhesive liquid on the panel before buffing the unit gives the clean finished surface.

- Equipped with PLC controlled pneumatic flow.

- Workpiece length min – 150 mm, edgebanding thickness up to 0.4 mm to 3 mm.

Buffing unit

- Edge banding machine buff wheels are used to polish and buff the edges of the top/bottom wood panels to create a smooth and glossy finish.

- Finishing the edge looks dimensional and attractive with this process.

Why Automatic Edge Bander UEB 860 PC Will Be The Perfect Choice For Your Business ?

Variable speed options for different production requirements

Full automation for uninterrupted edge processing

Perfect for laminated, MDF, particle board, and plywood

Built-in safety systems and reliable air-pressure integration

Heavy-duty frame minimizes vibration during high-speed operation

Delivers consistent quality – panel after panel

Have Any Question ?

WE ARE HAPPY TO HELP !

Explore More Woodworking Machines From Umaboy

UEB 640 PCGD Edge Banding Machine – With grooving and rough trimming

UEB 540 PC Edge Bander – Designed for advanced automation

UEB 310 C Edge Bander – Ideal for mid-scale production

Sliding Panel Saw 3200 A++ – For precise panel cutting